FAQ

If you are interested in our tank building system, please contact us via our web form or by phone. We will then discuss your project requirements and help you determine whether the Standard System with Roller Beds or the Advanced System with Wheel Trolley is your best fit.

Nordweld’s Tank Building System is delivered in 20-foot shipping containers. Depending on the size of your storage tank or project, additional components may be packed into a second container. All equipment is well-organized to facilitate easy unloading and loading, while also ensuring the goods are protected from damage during transportation.

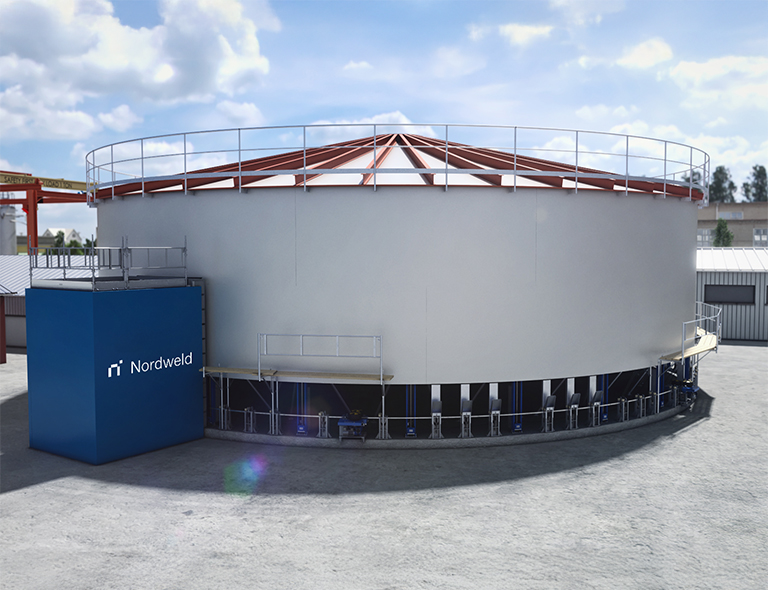

The system consists of electro-mechanical Lift Jacks, Tank Rotators, Roller Beds or Wheel Trolleys, a Tack Weld Stand and a Welding Station, all of which are packed in a 20-foot shipping container.

Yes, both our Standard System with Roller Beds and the Advanced System with Wheel Trolley include instructions that guide you through usage, assembly and dismantling. Upon request, we can provide on-site assistance during the assembly of the tank building system.

To ensure proper usage of our technology, it is important to follow the provided instructions and use skilled personnel. Workers must have experience operating welding machines and a basic understanding of electro-mechanical devices.

The number of workers required depends on the size of your project. In general, at least four workers are needed to construct a Ø20 m tank.

Normally, welding machines are not included.

To provide an accurate rental or purchase quote, we need the following information: material grade, tank diameter, weight and material thickness. If the tank height exceeds twice its diameter, wind conditions must also be given.

To provide an accurate quote, we require information on the material grade of the tank shell, thickness and the roof weight. This information is important to calculate the capacity of each wheel trolley to avoid damaging the edge of the plate that rolls on the trolley wheels.

It depends on the size of the tank. For example, assembling the equipment for a Ø20m tank typically takes two to three days, and a similar timeframe for dismantling.

Yes, our system can be delivered anywhere in the world. We arrange delivery to European ports from our workshop in Gorlice, Poland. For customers outside Europe, we use Incoterms FCA - Free carrier for delivery.

Our electro-mechanical Lift Jacks are easy and safe to operate, preventing oil leakage. The system is modular and allows expansion with add-ons such as a wheel trolley, vertical bending machine, and decoiler. It allows the rotation of the entire tank, enabling the assembly of all plates from a single location. Also, our system can be used in narrow spaces. Mechanized welding can be performed from one or two centralized locations, providing flexibility and efficiency. The system offers significant advantages when constructing tanks, improving the overall process.

The Standard System with Roller Beds is easy to operate and can be learned within a few days, significantly simplifying the tank construction process. The Advanced System with Wheel Trolley is more complex and requires a few additional training sessions to fully understand. Proper setup of the jacking equipment, the vertical bending, and the in-feeding point alignment are important when using the Advanced system. Nordweld’s technicians can provide training and support to ensure smooth implementation and operation of the system.

We provide a one-year mechanical warranty starting from the date you receive the equipment. Further details about the warranty can be found on our website, under Documentation/General terms of purchase.

Yes, our Advance System can be used to construct directly from coil. The maximum coil load capacity is 25 tons, with material thicknesses of up to 10mm for LDX/Duplex material, 12mm for 308/316 materials and 16mm for CS materials. The maximum coil width is 2000mm.

Our system can handle tanks with a minimum size of Ø7m and a maximum of Ø 45-50m. However, the maximum diameter depends on the total lifting weight and shell thickness.