How to reduce the costs of building industrial tanks and speed up processes? Comparison of traditional methods with the innovative Nordweld system.

Traditional tank erection methods often rely on cranes, scaffolding, and manual welding. These approaches present multiple challenges:

- High labor costs – manual lifting, positioning, and tank welding extend the construction process.

- Safety risks – working at height increases the risk of accidents and requires scaffolding.

- Low efficiency – handling field-erected storage tanks with cranes requires complex logistics.

- Longer timelines – traditional tank construction methods can significantly delay project delivery.

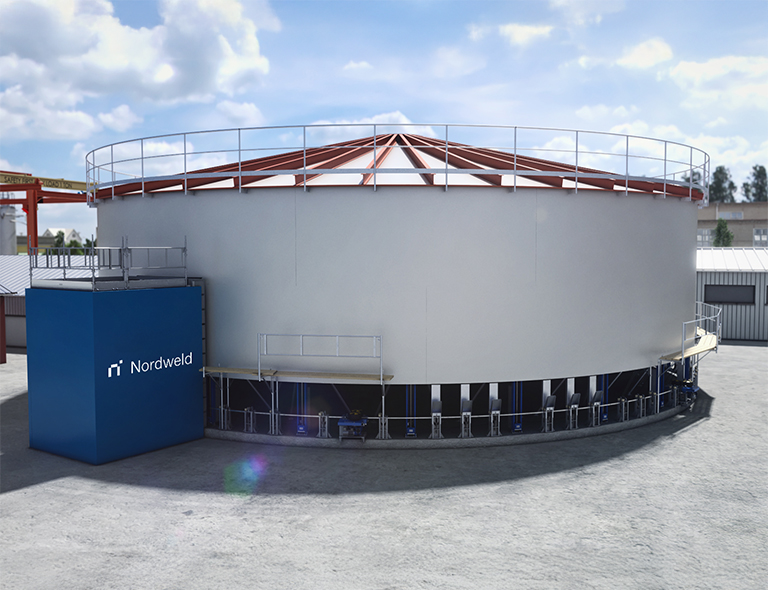

Nordweld tank building system – alternative to tank jacking equipment

The Nordweld tank construction system offers a safer and faster approach to tank construction, minimizing the need for conventional tank lifting systems. It utilizes electromechanical lifting devices and a rotational assembly process, resulting in significant savings in time, labor, and materials.

Faster tank erection with lower labor costs

- The tank is rotated during assembly, allowing for continuous welding using an automatic girth welder from a single position.

- Shell plates are prepared from flat sheet or coil and shaped on-site using a vertical bending machine and decoiler.

- Compared to conventional tank jacking systems, projects can be completed up to 40% faster, depending on setup.

- Ideal for building above-ground storage tanks, steel water tanks, and stainless steel tanks.

Improved safety and welding efficiency

- All work is carried out at ground level, eliminating scaffolding and high-risk operations typical in tank jacking projects.

- Automated girth welders ensure high-quality, consistent welds, minimizing the need for manual correction.

- The system reduces crane usage, improving safety and cutting rental costs.

Lower material waste and optimized logistics

- Using coil or flat plates bent on-site reduces vertical seams and material waste — a clear advantage over traditional welded steel tanks.

- The Advanced System eliminates the need for welded lifting beams by using trolley jacks.

- Fewer steps in the setup and lifting phase compared to older hydraulic tank jacking systems or similar jacking devices.

Traditional tank jacking system vs. Nordweld system: cost and time comparison

| Building method | Traditional method | Nordweld Standard System |

| Tank downtime | 6-8 weeks | 4 weeks |

| Crane rental costs | Very high | Minimal use |

| Safety risk | High (working at height) | Lower (ground-level work) |

| Welding efficiency | Manual welding | Automated |

| Total project cost | 100% | 30–40% savings |

A smarter tank construction method for modern industry

The Nordweld tank building system provides a flexible, modular, and highly automated solution for tank erection. It is an excellent alternative to traditional tank jacking equipment, ideal for companies constructing steel storage tanks, SS tanks, or field-erected tanks in tight or complex job sites.

Key advantages:

- Shorter project timelines – up to 40% faster.

- No scaffolding – all work done at ground level.

- Reduced labor needs – fewer operators and hours.

- Improved weld quality – consistent and automated.

Contact us – we will tell you how the Nordweld system will improve your investment in steel tanks.

Read our other news

Meet us at StocExpo 2026

Nordweld receives UL Certification – a milestone in industrial machinery quality and safety