Our system as an innovation for industry

Steel storage tanks are a key element in nearly every industry, as they allow for the storage of various materials such as chemicals, oil, gas, food, pulp, waste, water, and more.

Steel tanks are made from different types of steel, selected based on the material to be stored. Choosing the right material for tank construction helps prevent corrosion and minimizes costs. The optimal solution is to use steel with high mechanical properties.

Traditional method of steel tank construction

The traditional method of building steel storage tanks requires a skilled engineering team, a crane to lift the tank elements, and scaffolding to enable workers to reach the top of the structure. This process requires a large amount of space, significant financial investment, and considerable time to complete.

Creators of the Nordweld Tank Building System

Niklas Nordin and Lennart Karlsson are the creators of the Nordweld Tank Building System. Nordin has been working in the tank construction industry since 1988, while Karlsson is a mechanical design engineer with over 40 years of experience in the field.

In 1999, Nordin and Karlsson developed and successfully tested the first generation of the Tank Building System with the core idea being to rotate the entire tank and weld the elements mechanically.

The Evolution of the Nordweld Tank Building System

In the following years, Nordin continuously developed the system. In 2014, Nordin and Karlsson launched the third and current generation of the system, which focuses on maximizing tank capacity, system flexibility, and ease of use.

Founding of Nordweld TBS

In 2017, Nordin and Karlsson founded Nordweld, which partnered with TLC Sp. z o.o., a leader in architectural steelwork in Poland.

New solution for steel tank construction

In 2018, Nordweld introduced an additional innovation – a wheel trolley, which significantly facilitates the construction of tanks made from coil steel.

The Nordweld Tank Building System

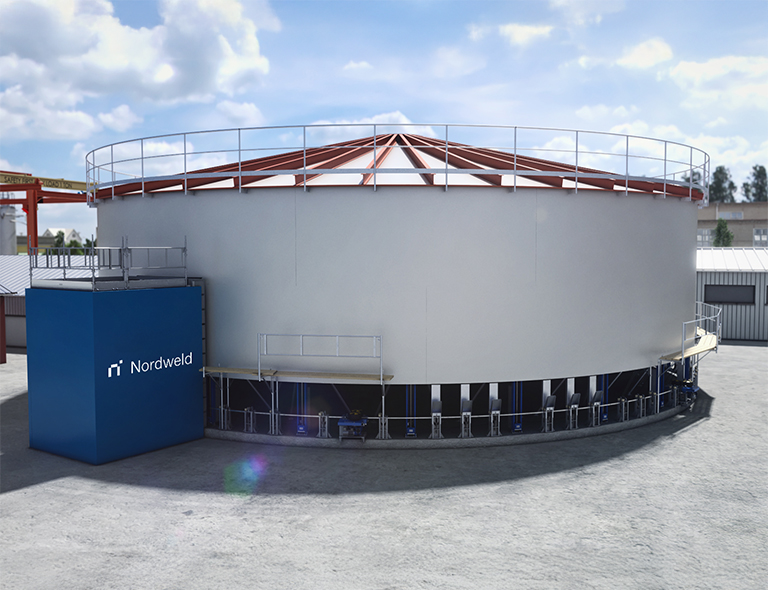

The Tank Building System developed by Nordweld is a standalone method available for rent at any time. It is dedicated to any company involved in the construction of steel storage tanks. This innovative solution enables time and cost savings on project investments. Moreover, with the top-down construction method, no crane or scaffolding is needed, allowing tanks to be safely built at ground level, even in tight industrial spaces.

The system is delivered to the client in a cargo container and includes everything needed to start the construction of steel tanks. Additionally, a qualified consultant can be present on-site to assist with equipment setup and offer support if any issues arise.

Contact us

For more information on renting the Nordweld Tank Building System, please contact us

To find out more about TLC visit www.tlc.eu

Read our other news

Meet us at StocExpo 2026

How to reduce the costs of building industrial tanks and speed up processes? Comparison of traditional methods with the innovative Nordweld system.