We are excited to announce the completion of two tanks built with the advanced system for the wine industry in the picturesque Bordeaux region. These modern tanks feature a diameter of 16.47 m and a height of 16.8 m, with an impressive capacity of 3,400 m³. They are made of LDX 2101 material, which ensures exceptional quality and durability.

How did we achieve such remarkable results?

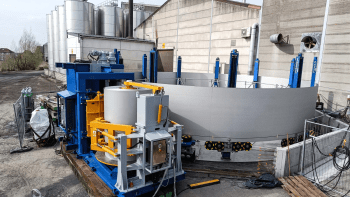

All thanks to our advanced system. By utilizing innovative equipment such as Wheel Trolleys, a Bending Machine, and a Decoiler, we executed the project efficiently while maintaining the highest quality standards.

What are the advantages of advanced system?

- High Capacity

We can construct large and heavy tanks (1,000–10,000 m³) directly from coil.

- Cost-Effective Material

Coil material is more economical compared to flat sheet material (approx. 5-8% in price).

- No Pre-Rolling

Material handling in the workshop is unnecessary.

- Efficient Welding

Plasma welding is effective up to 10mm, one pass from one side, a single vertical weld reduces the amount of welding and required non-destructive testing (NDT).

- Logistics

Building from coil requires less storage and transport space of the material.

- Superior Quality

The tank shell quality is significantly higher compared to traditional methods.

- Labor Efficiency

Fewer personnel and man-hours are needed, resulting in a construction time approximately 100-150% faster than conventional methods.

The completed project in Bordeaux is not just another milestone - it is a perfect example of how innovation can transform the industry!