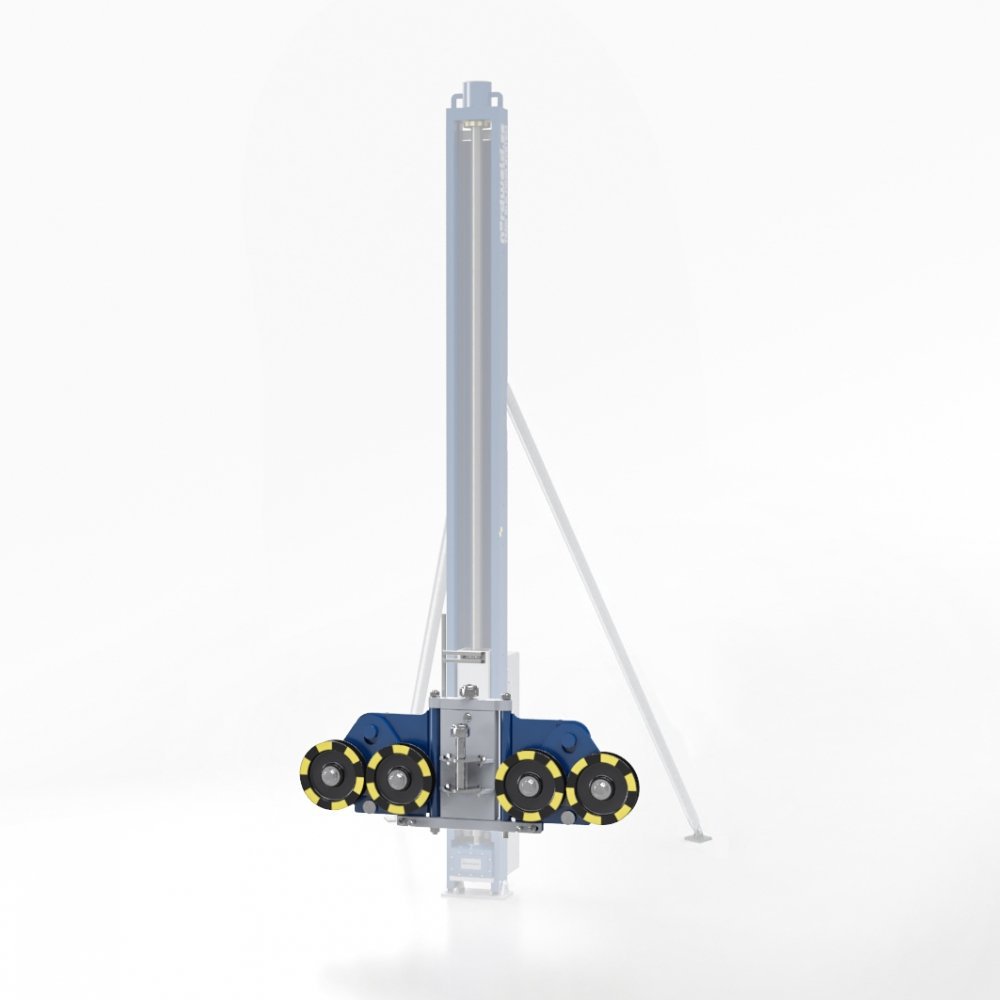

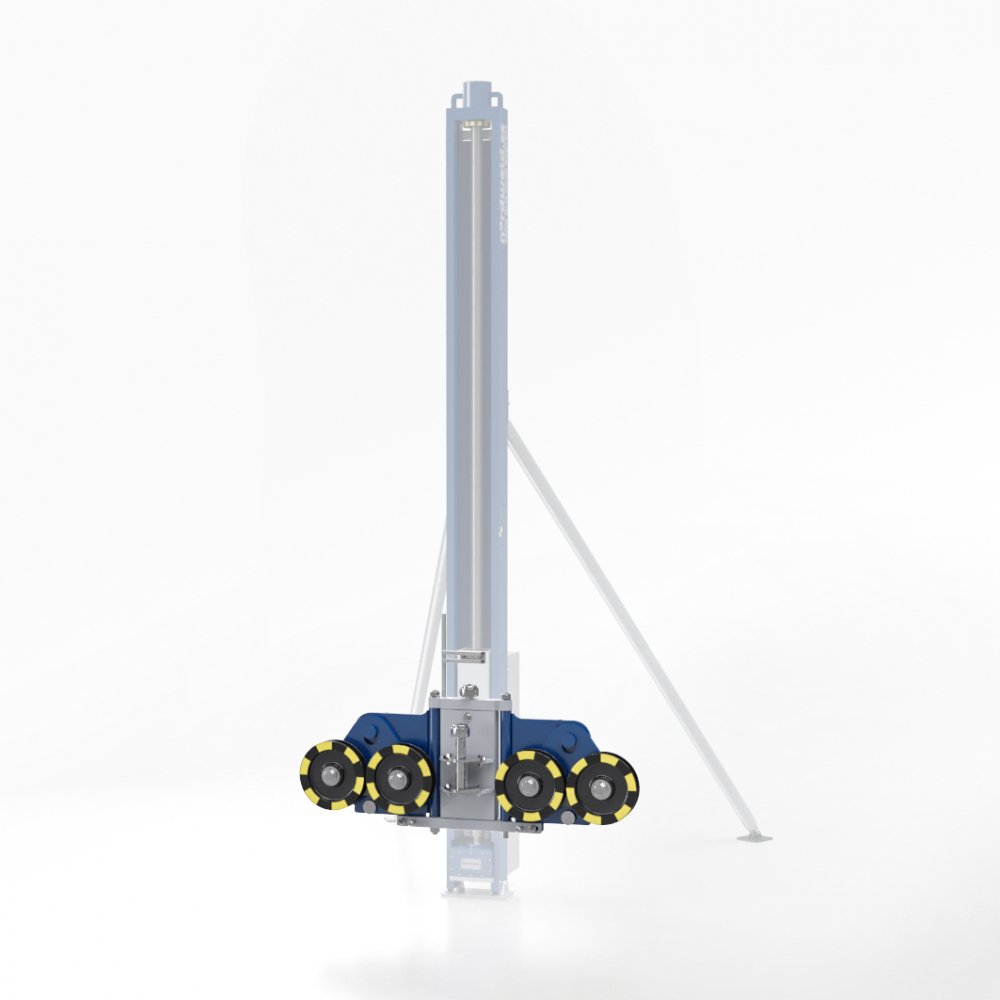

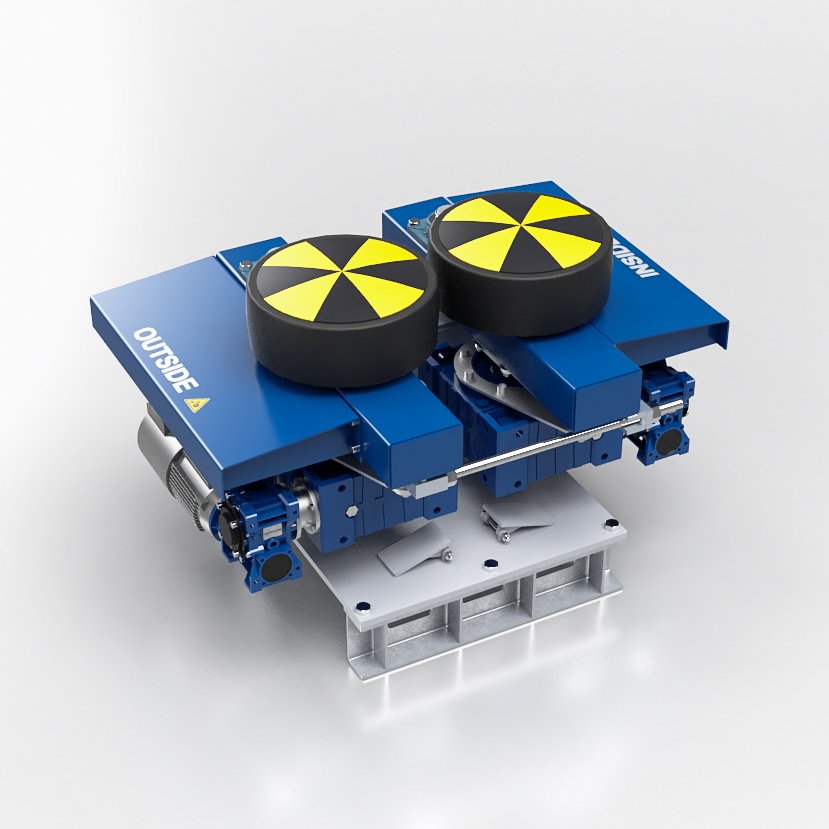

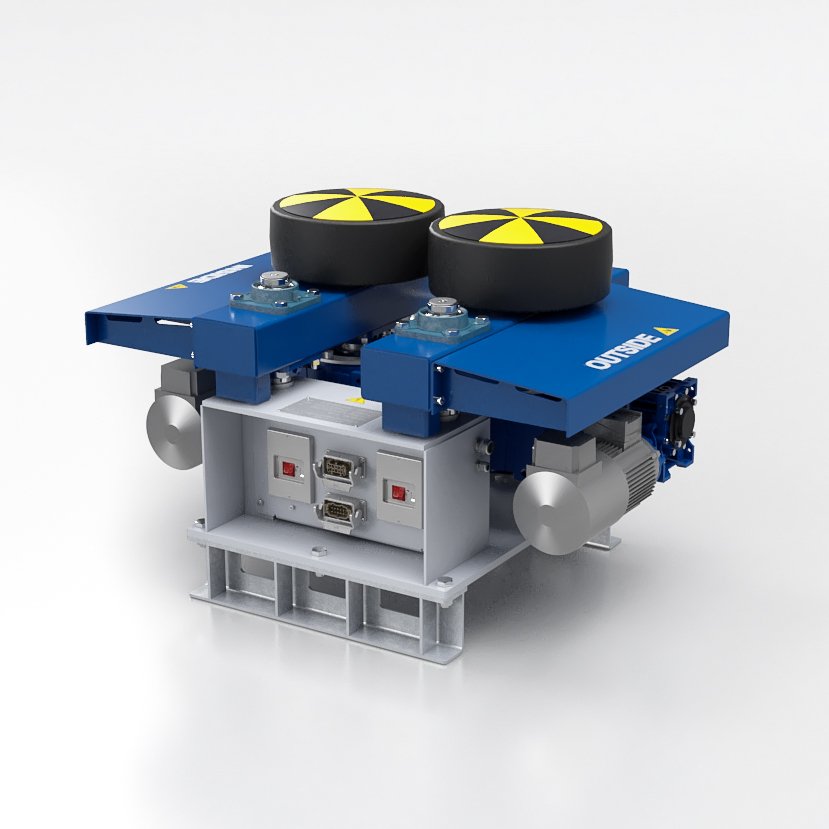

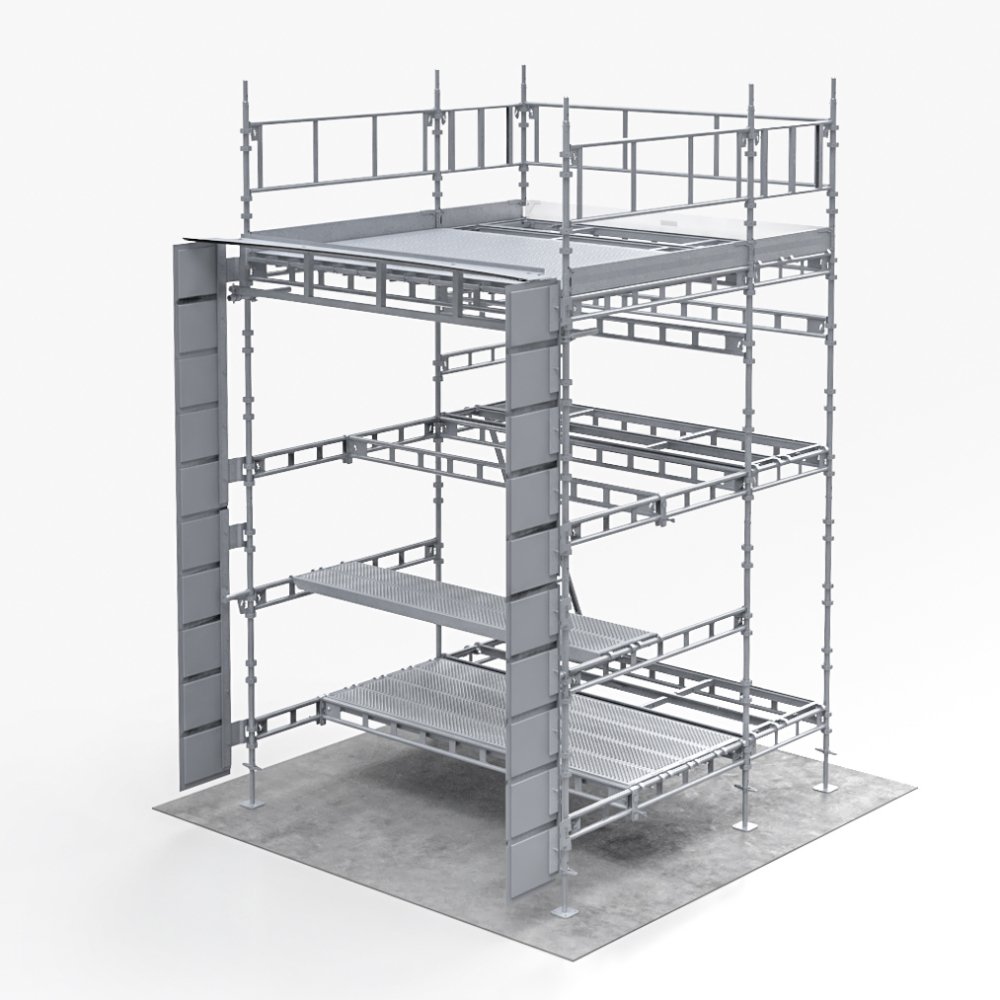

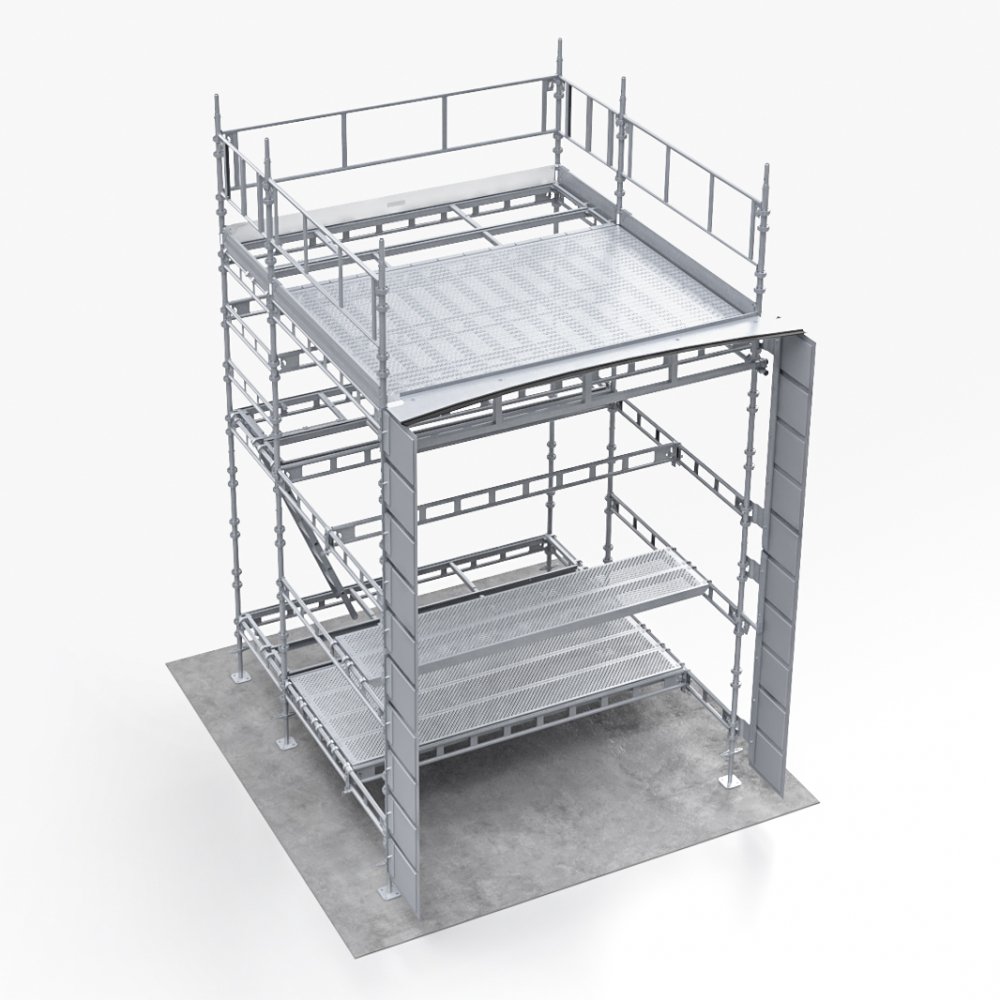

Standard system with roller beds

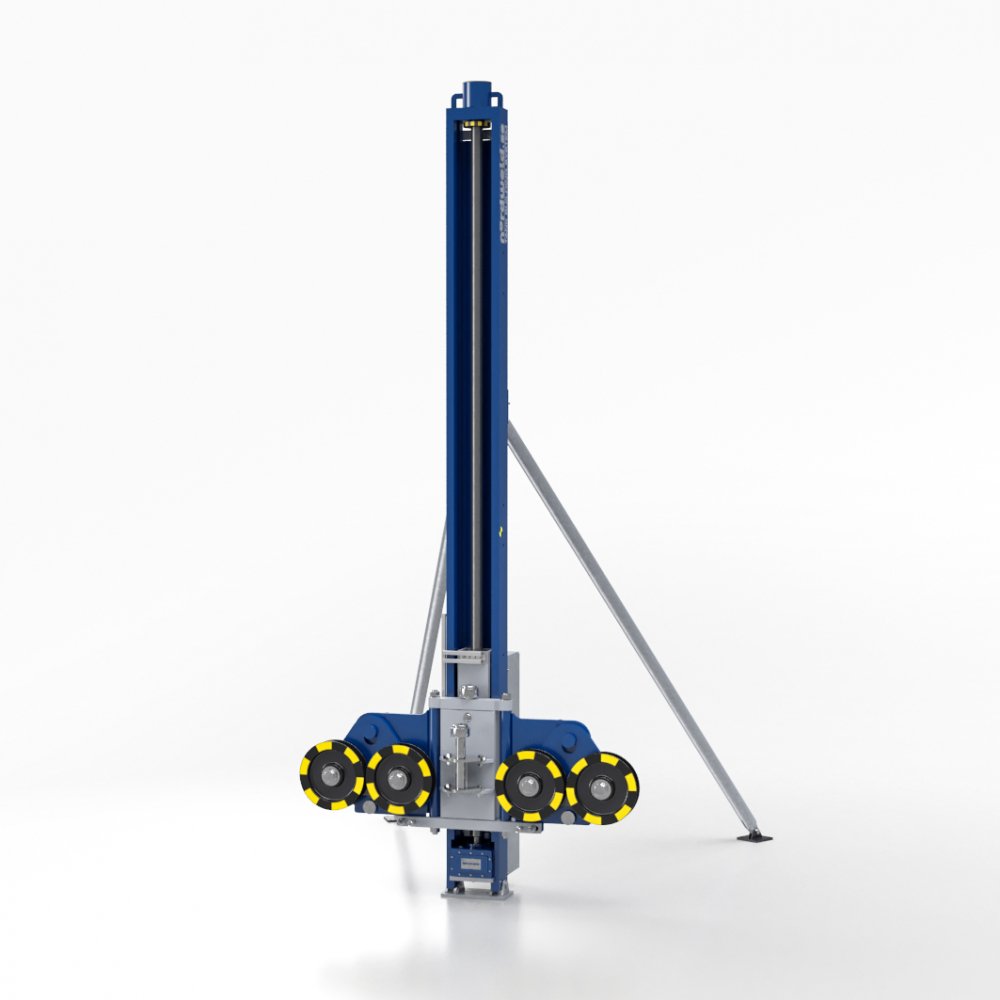

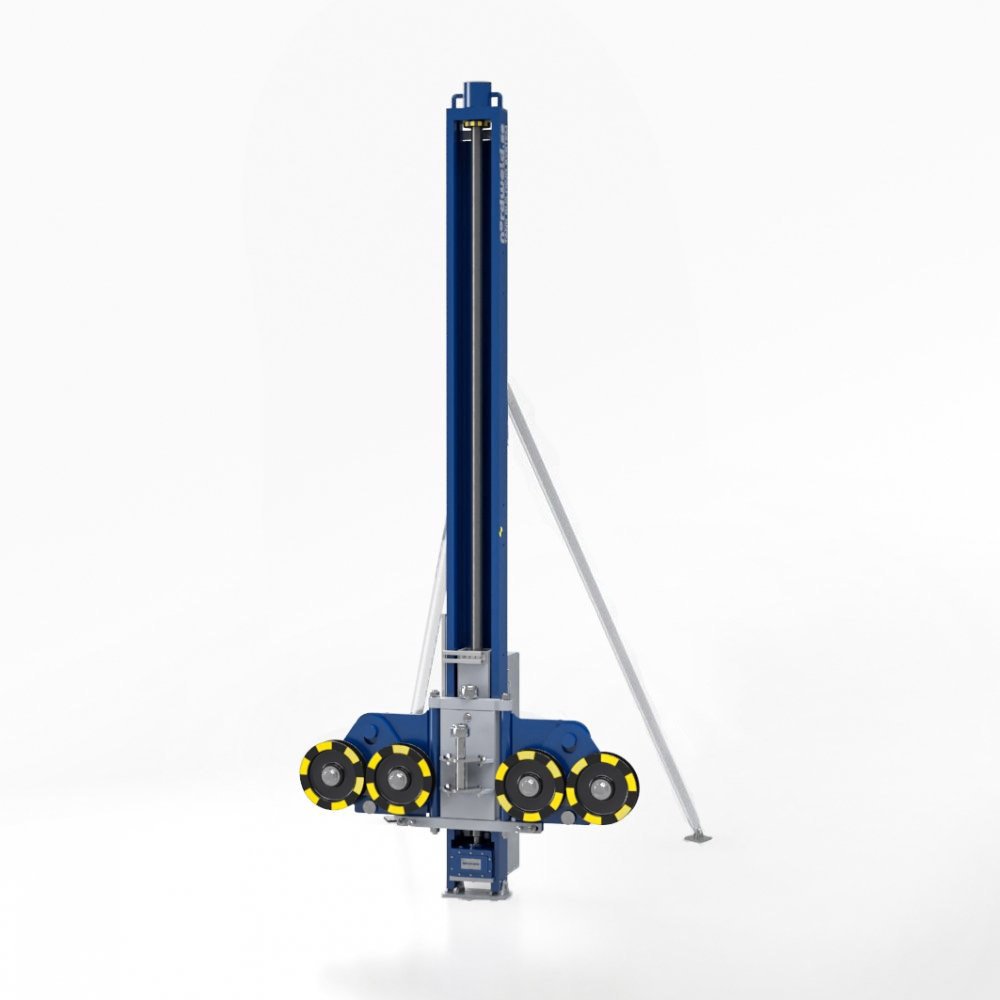

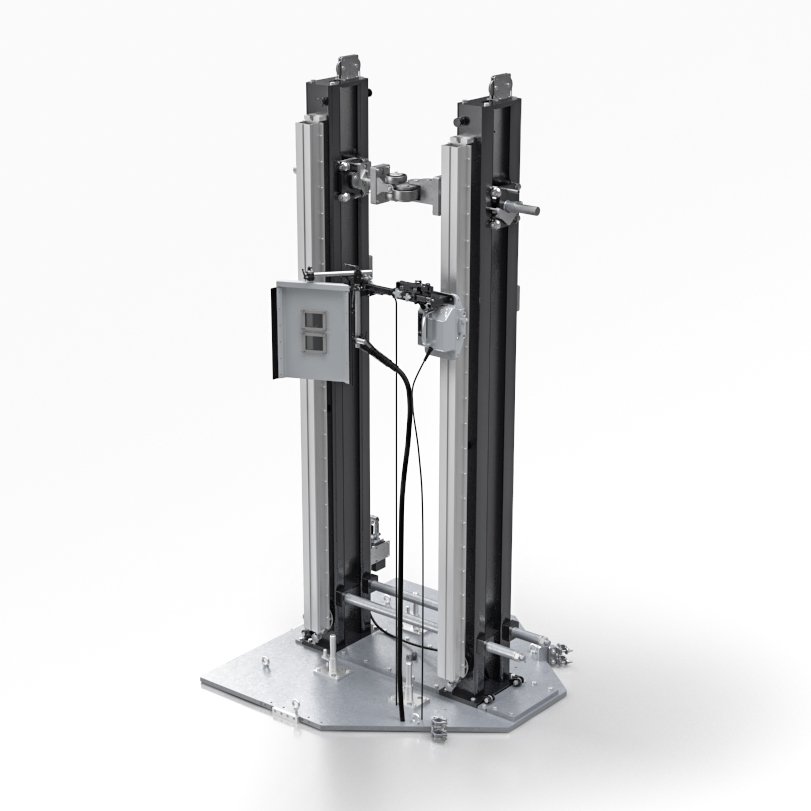

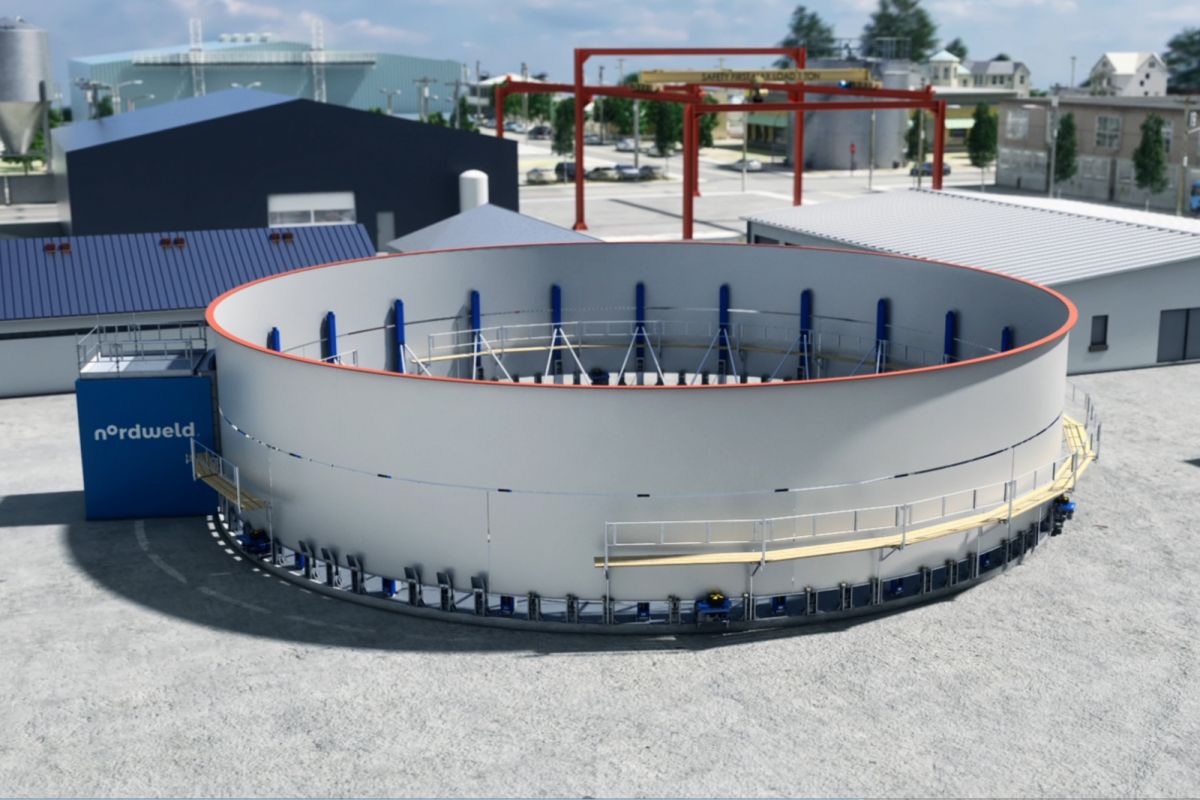

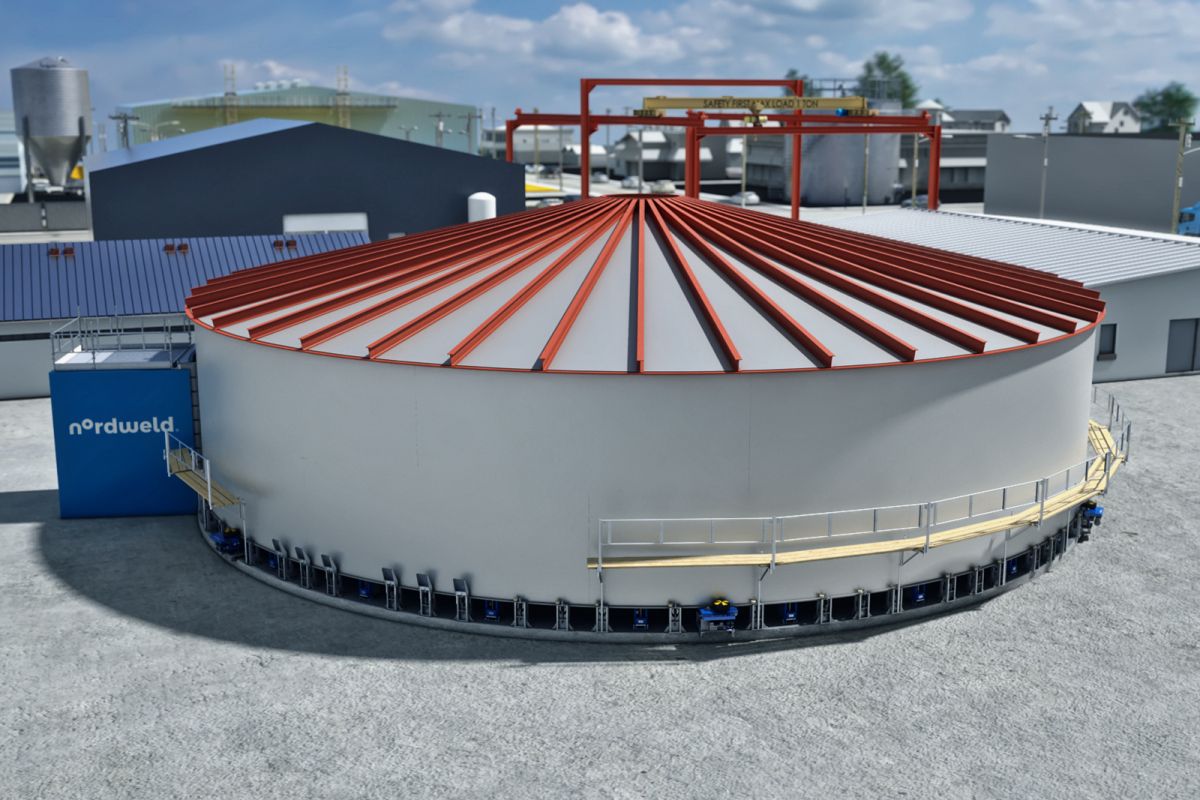

Advanced system with decoiler/ bending machine

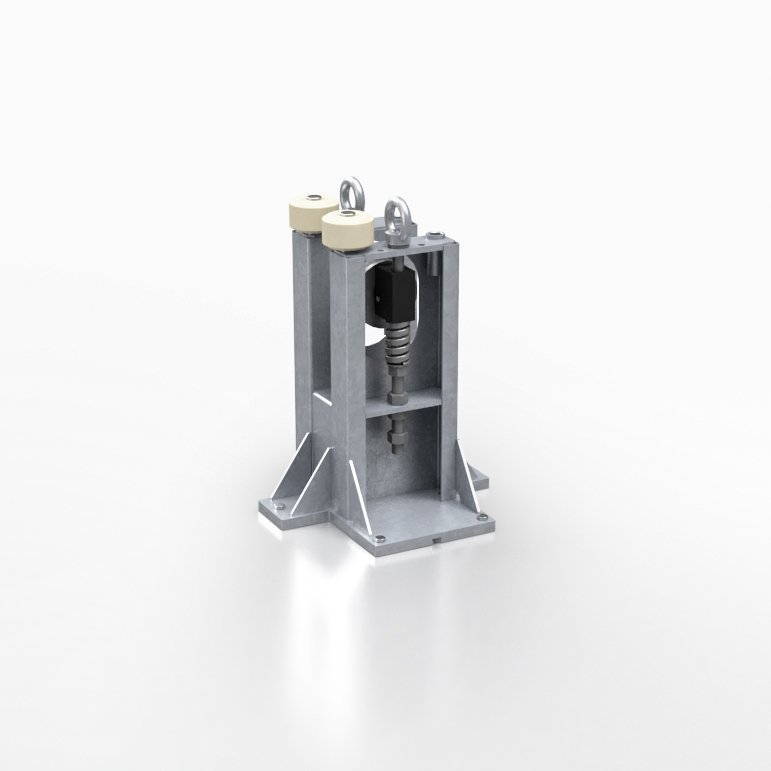

Nordweld’s Automated Tank Building System uses the “Top-Down” method of construction. All shell plates are loaded and fed individually from one location and then rotated around the tank’s periphery. The system consists of 15 ton electro-mechanical Lift Jacks, Roller Beds, Trolley (optional), Tank Rotators, a Welding Station and a Tac weld / welding stand. As the tank is being constructed, it is continually rotated, with all shell joints welded, as well as the attachment of any required nozzles. The system utilizes a mechanised welding processes, designed and refined over many years of continual research and development.

The maximum diameter of a tank built with our technology is 50 meters with maximum capacity of 700 metric tons. Height of a tank depends on its diameter and other factors that have to be taken into consideration (e.g. wind, tank weight, etc.).

Standard system with roller beds offers the basic method of building storage tanks. It is a perfect solution if you are constructing tanks from prefabricated, already bent steel sheets.

Advanced system with decoiler/ bending machine will meet your requirements if you wish to build a storage tank from steel from coil, or prefer to feed the machine with prefabricated flat steel sheets. Everything is then done automatically.

Watch the animation on the left to learn how they work.