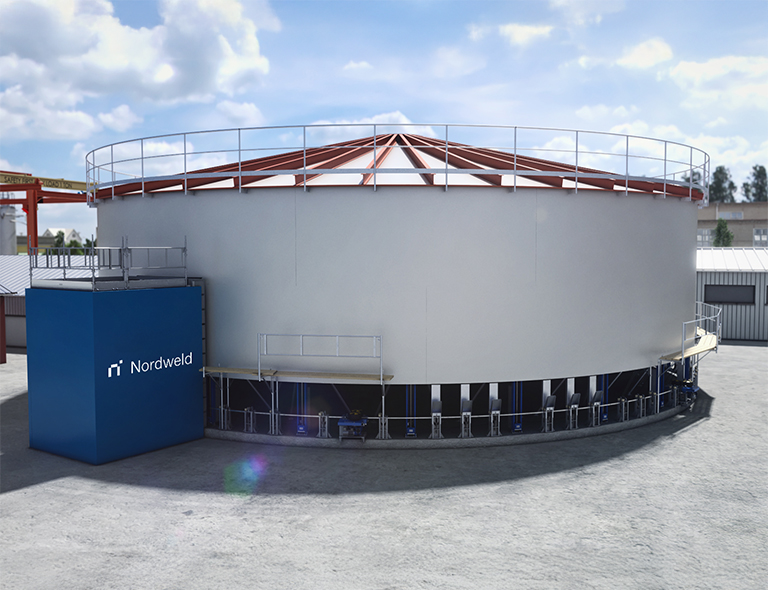

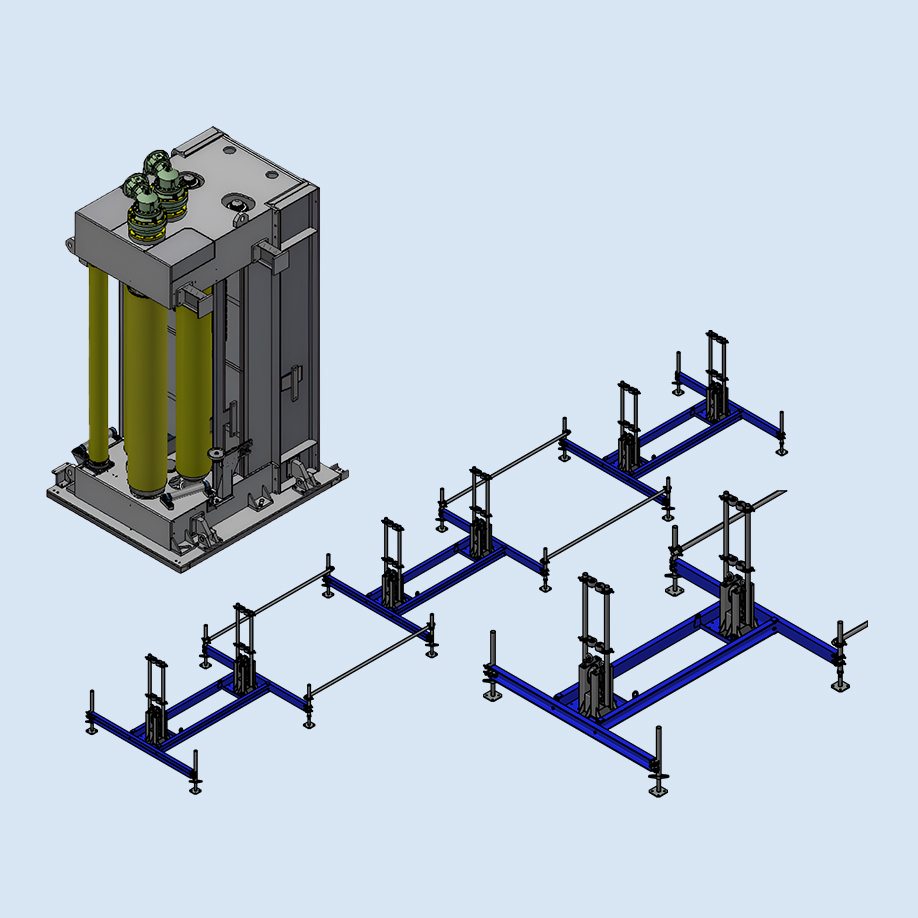

Vertical Plate Bending Machine + Plate Track

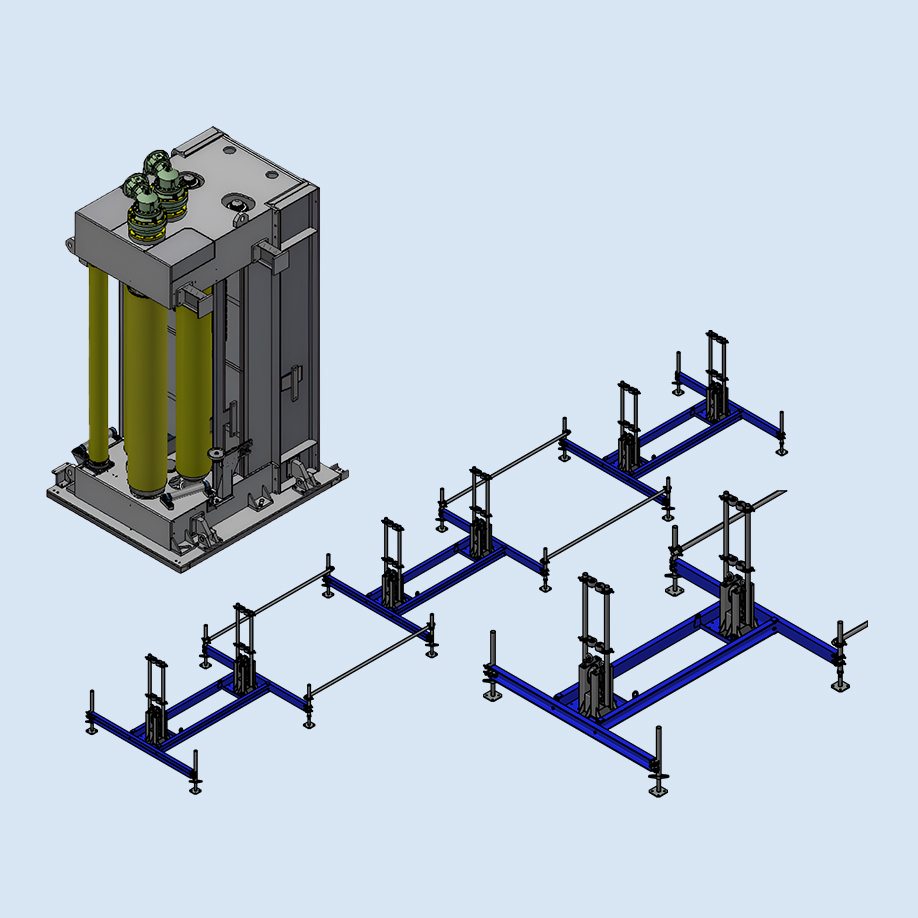

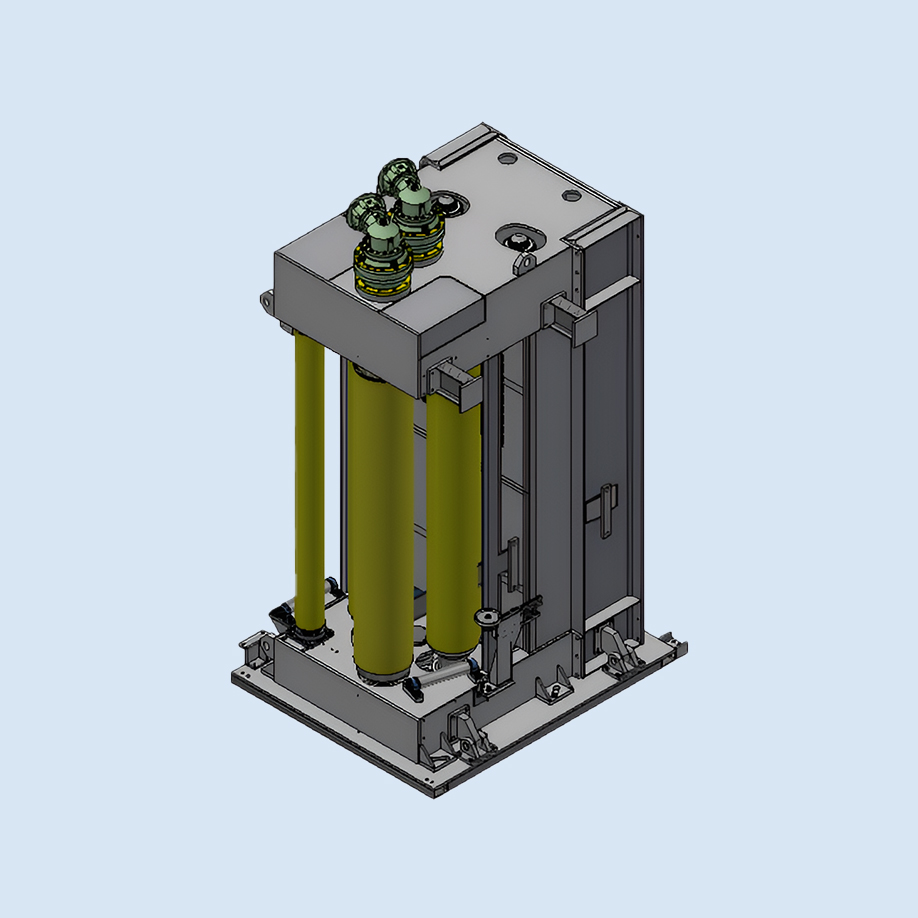

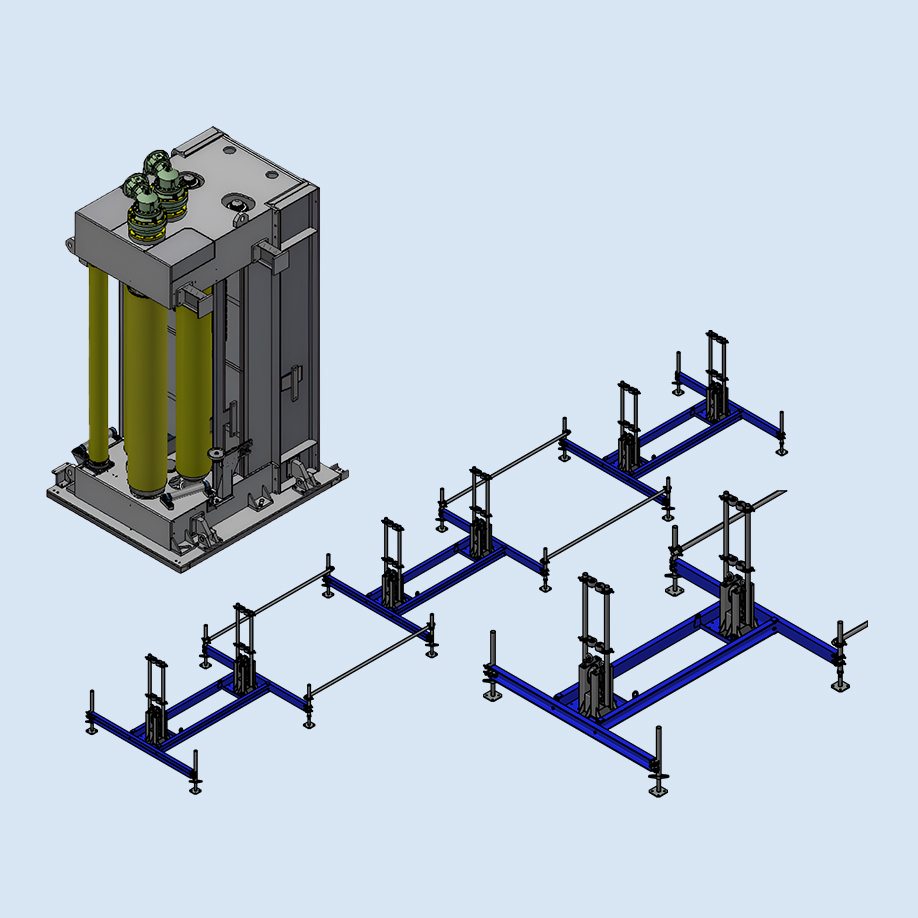

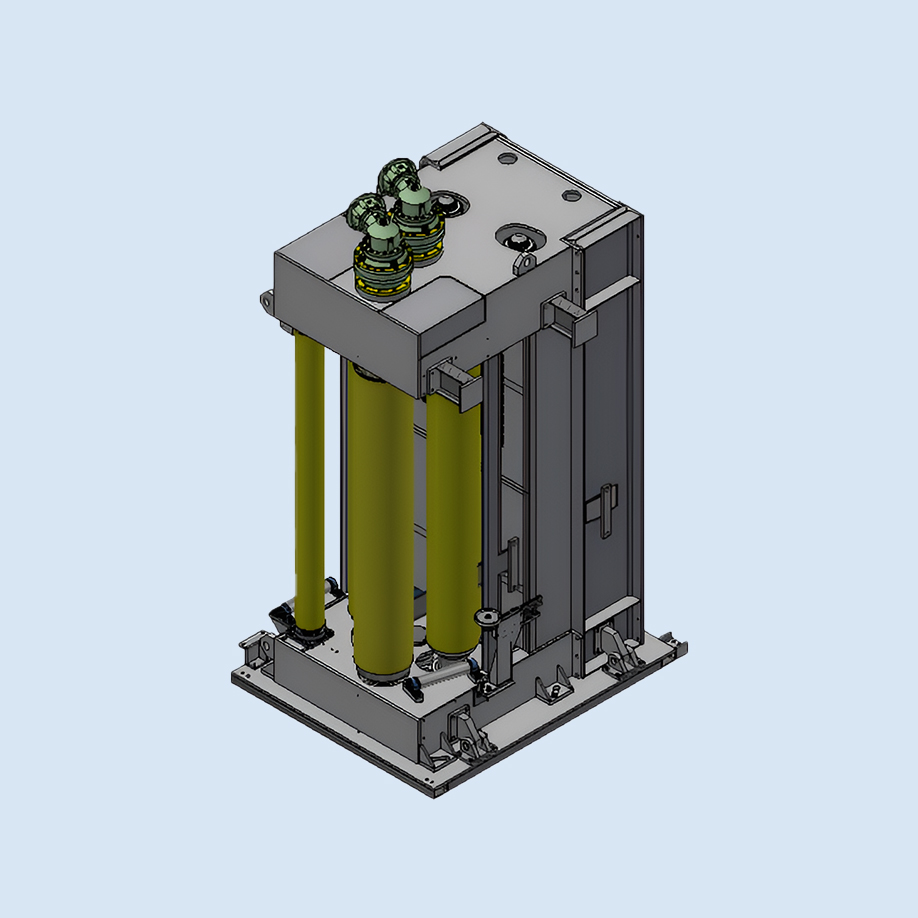

The vertical plate bending machine is designed for rolling straight plates or material from coils. It can be equipped with either 3, 4, or 7 rolls, and can be customized to accommodate different plate heights and thicknesses. The rolls are covered with urethane to prevent contamination of the rolled material. The machine is connected to a de-coiler for processing material directly from coils, which can be equipped with a hydraulic tilting function for easy loading of new coils. A telescopic arm aids in feeding the coil into the bending machine. Both the vertical bending machine and the de-coiler are operated via remote control.

Ask for an offer

The unique characteristics

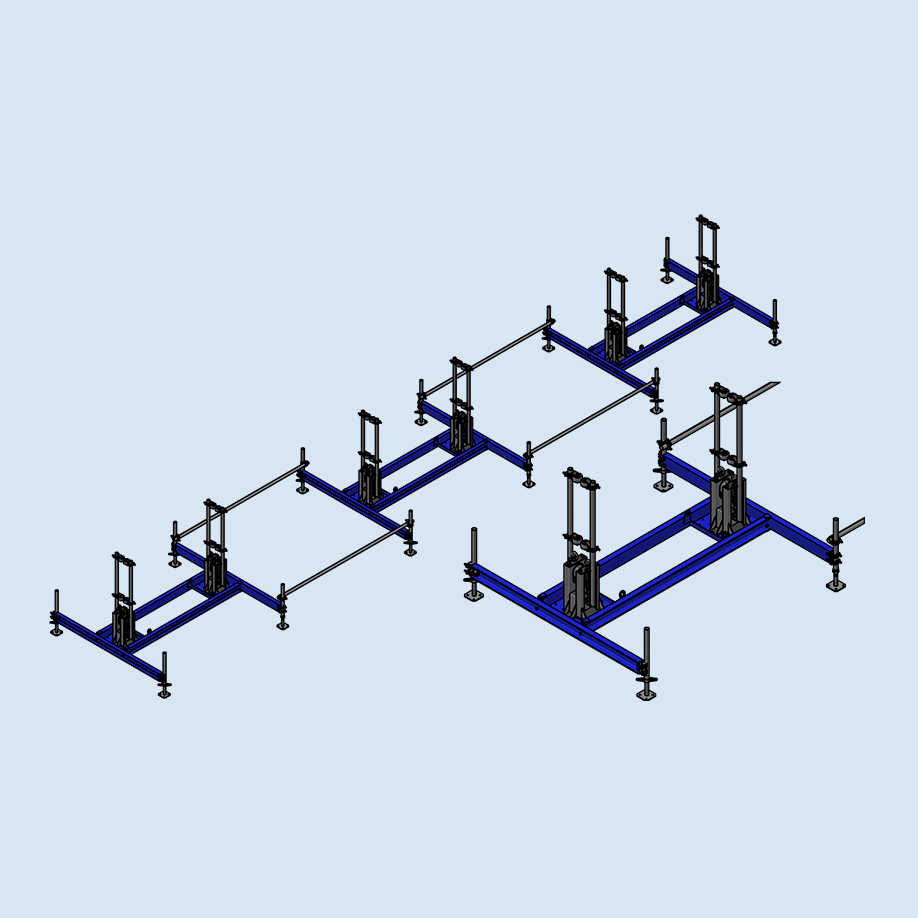

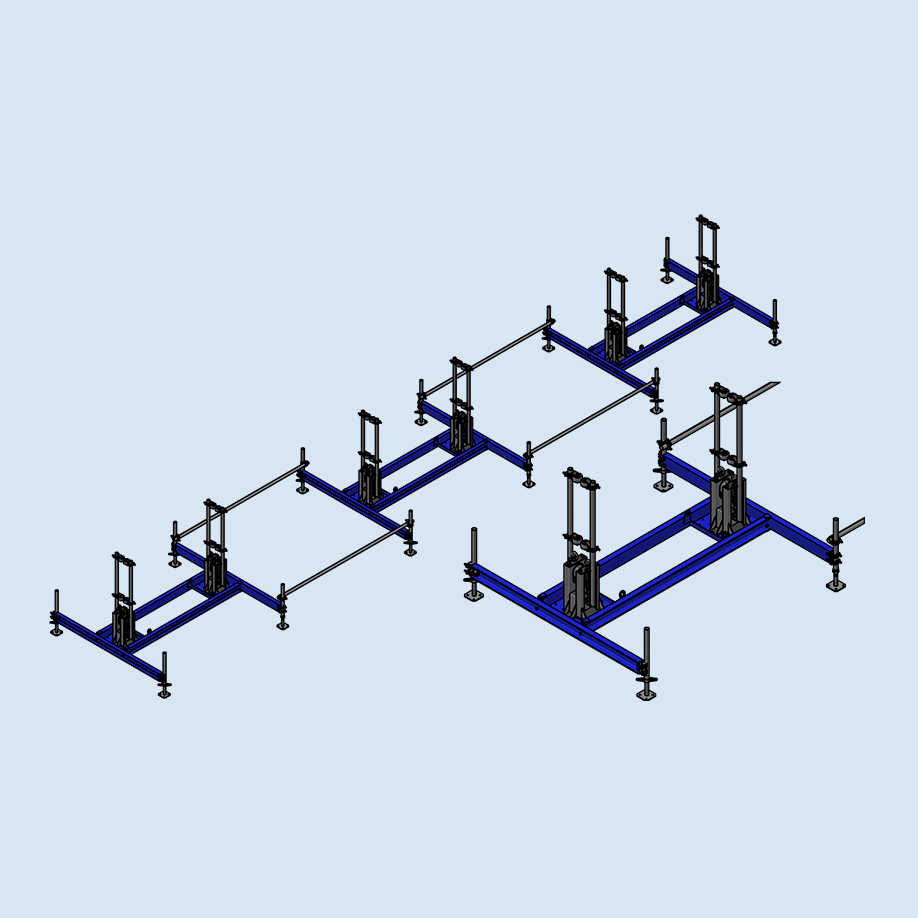

Used in conjunction with a vertical bending machine, place flat material onto the plate track and weld the vertical seams. Next, roll the long sheet and feed it into the jacking system.

Advantages:

• roll the material onsite

• weld and prepare the sheet meanwhile the circumference on the tank is welded

• easy to mechanize the welding

• better shape of the tank wall

Product dimensions

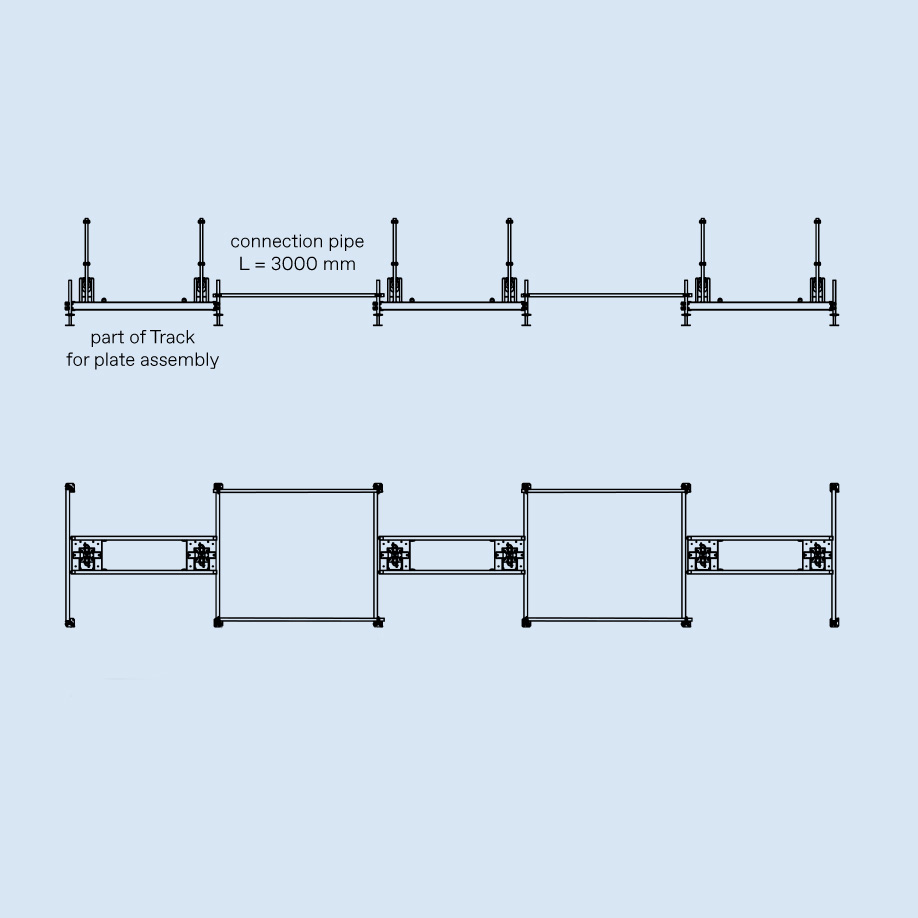

Plate track 1 section dimensions (2648 mm – 5502 mm).