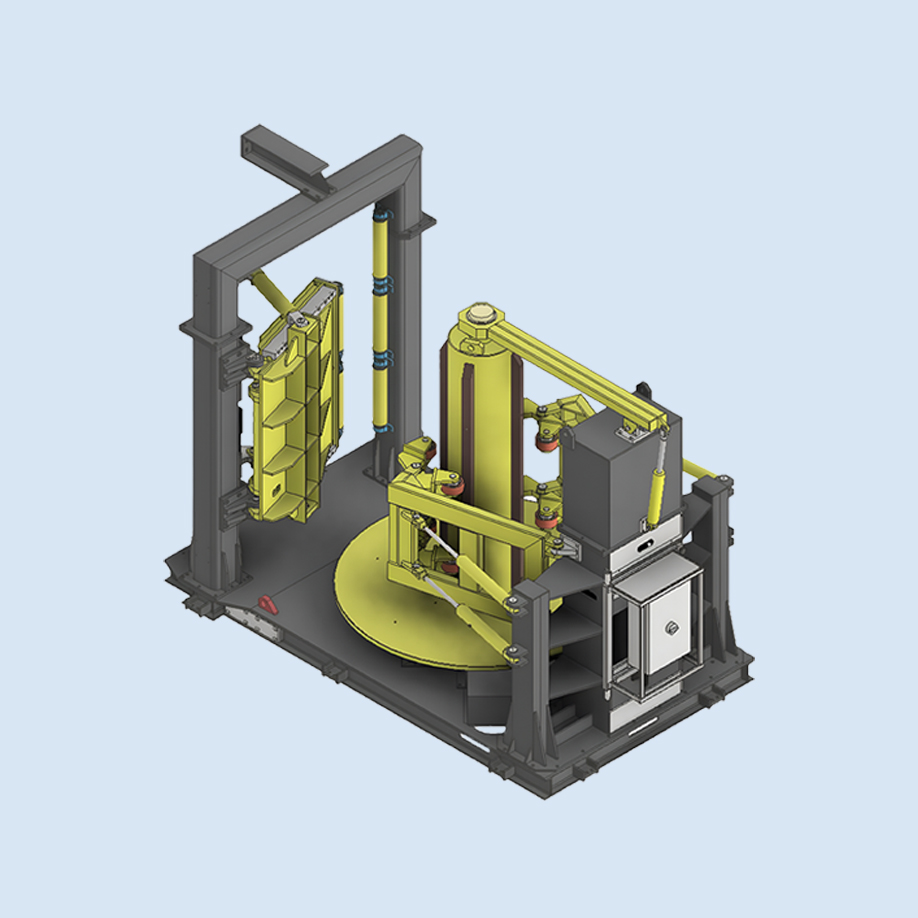

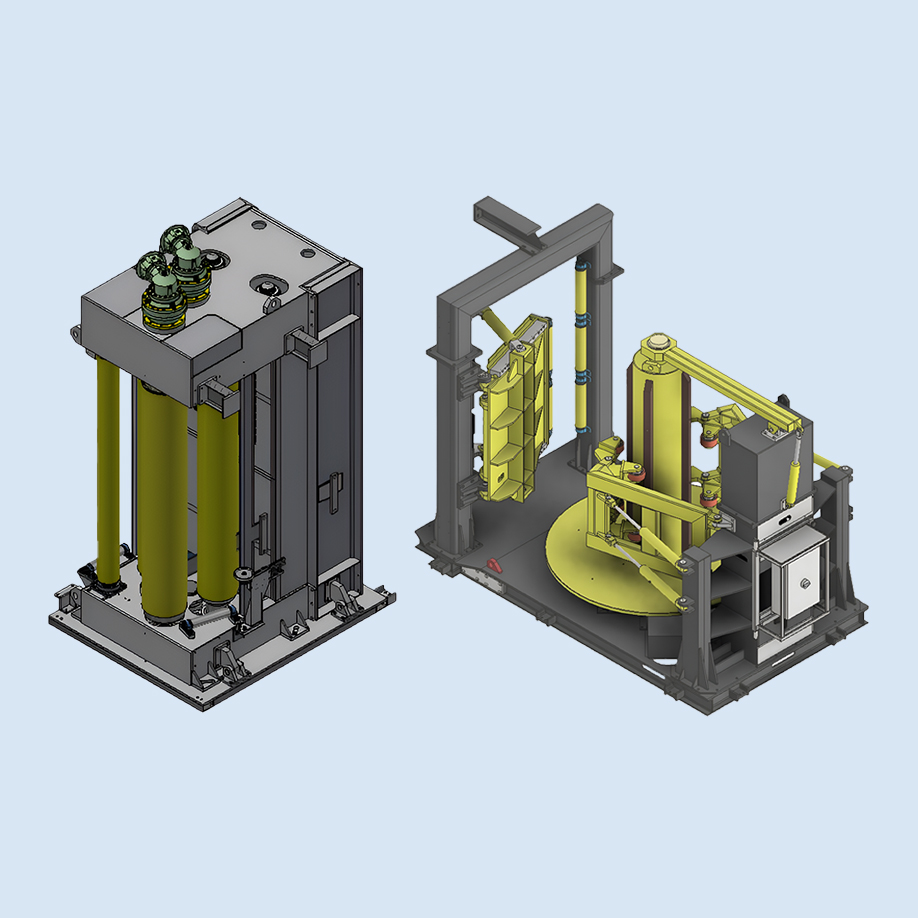

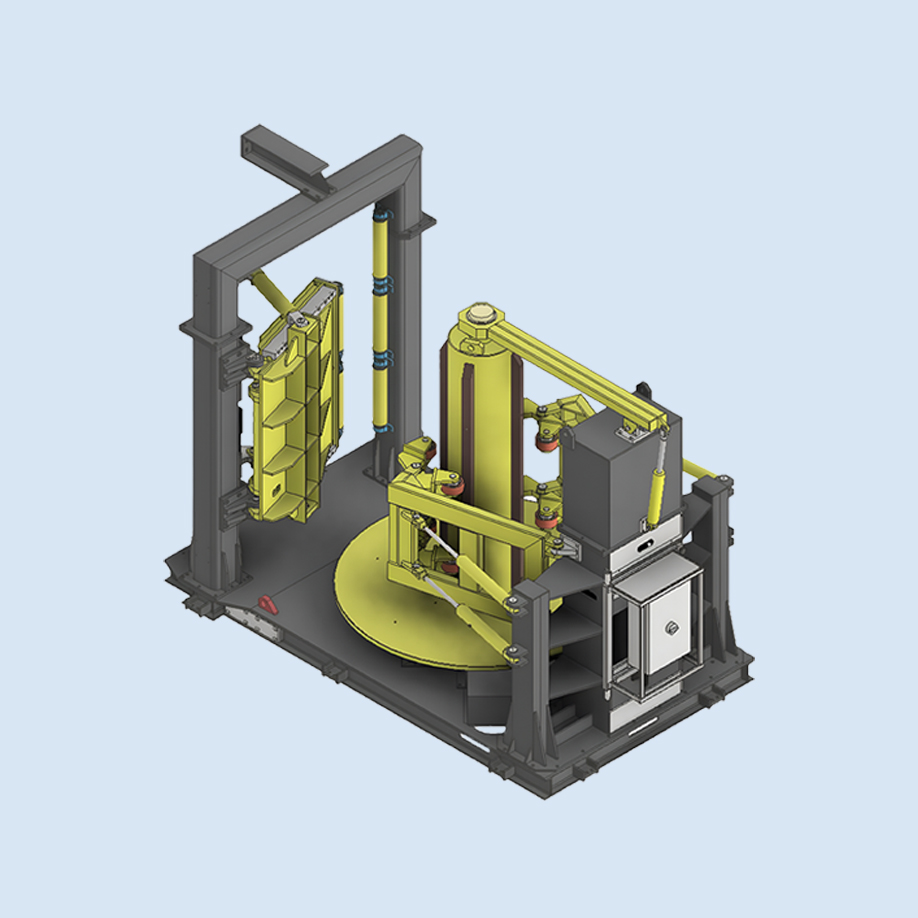

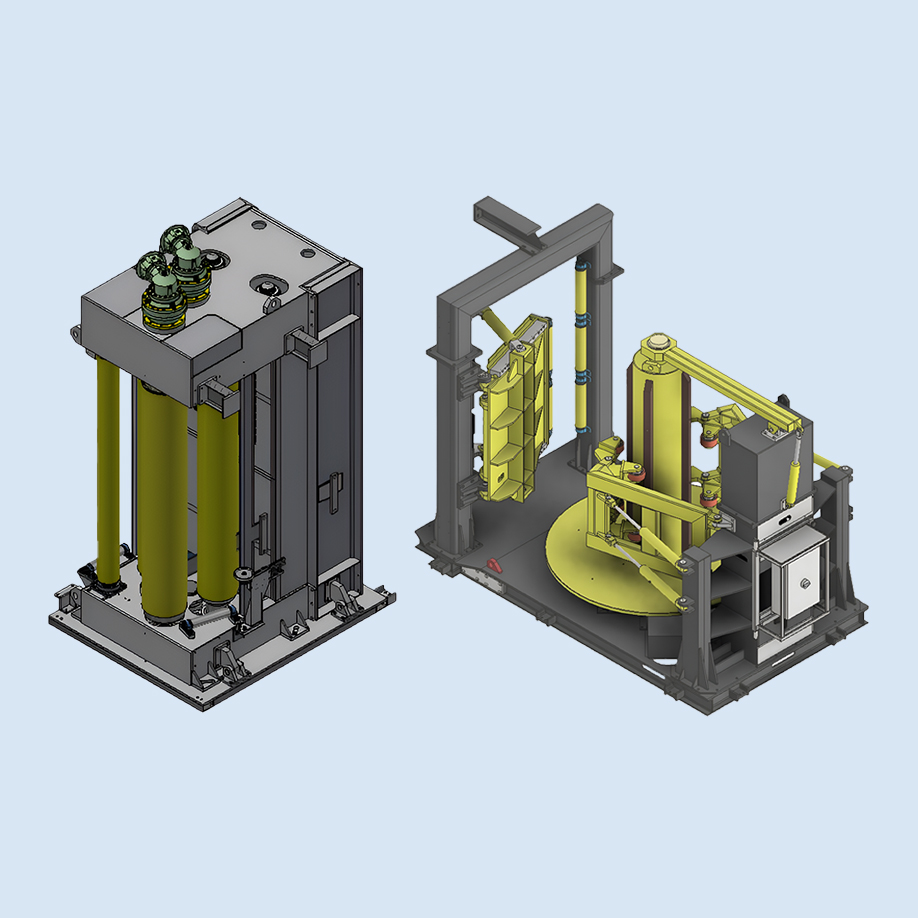

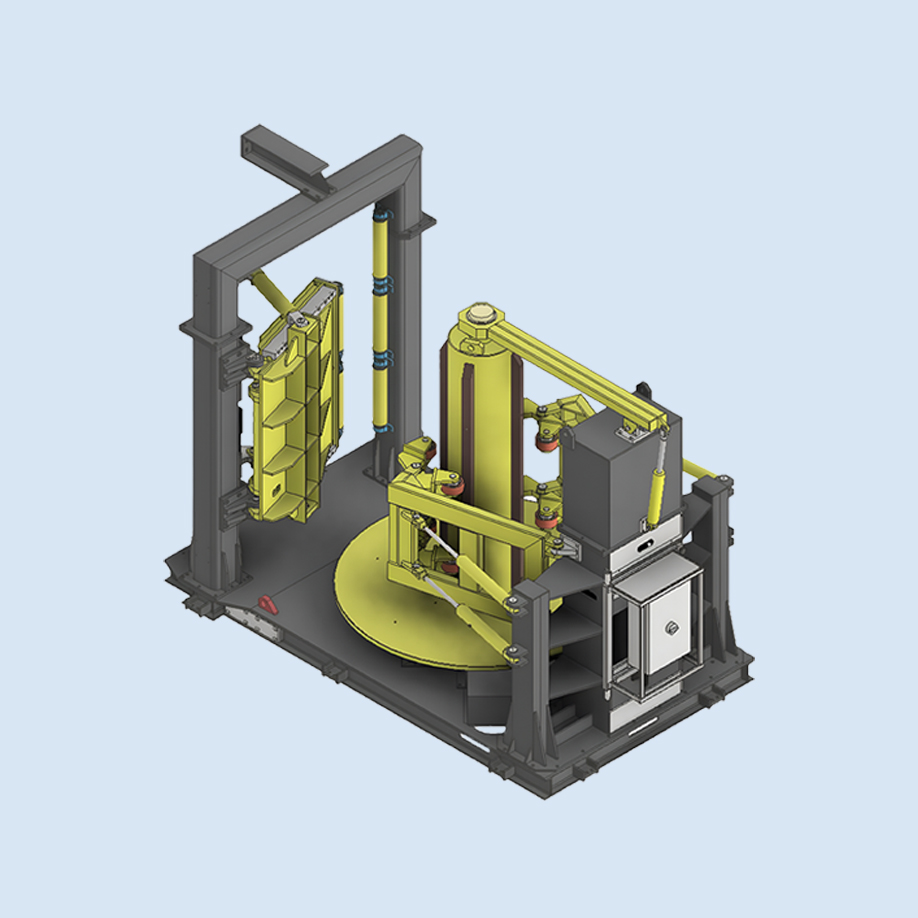

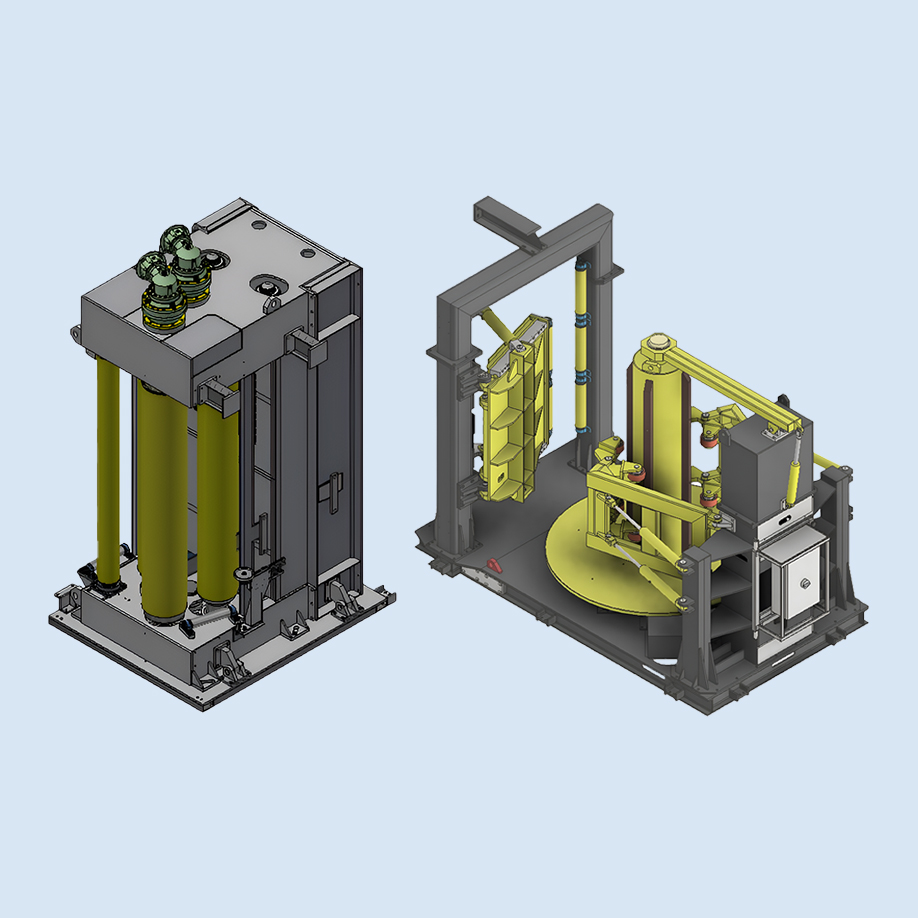

Vertical Plate Bending Machine + Decoiler

The vertical plate bending machine is designed for rolling straight plates or material from coils. It can be equipped with either 3, 4, or 7 rolls, and can be customized to accommodate different plate heights and thicknesses. The rolls are covered with urethane to prevent contamination of the rolled material. The machine is connected to a de-coiler for processing material directly from coils, which can be equipped with a hydraulic tilting function for easy loading of new coils. A telescopic arm aids in feeding the coil into the bending machine. Both the vertical bending machine and the de-coiler are operated via remote control.

Ask for an offer

The unique characteristics

The vertical plate bending machine is designed for rolling straight plates or material from coils. It can be equipped with either 3, 4, or 7 rolls, and can be customized to accommodate different plate heights and thicknesses. The rolls are covered with urethane to prevent contamination of the rolled material. The machine is connected to a de-coiler for processing material directly from coils, which can be equipped with a hydraulic tilting function for easy loading of new coils. A telescopic arm aids in feeding the coil into the bending machine. Both the vertical bending machine and the de-coiler are operated via remote control.

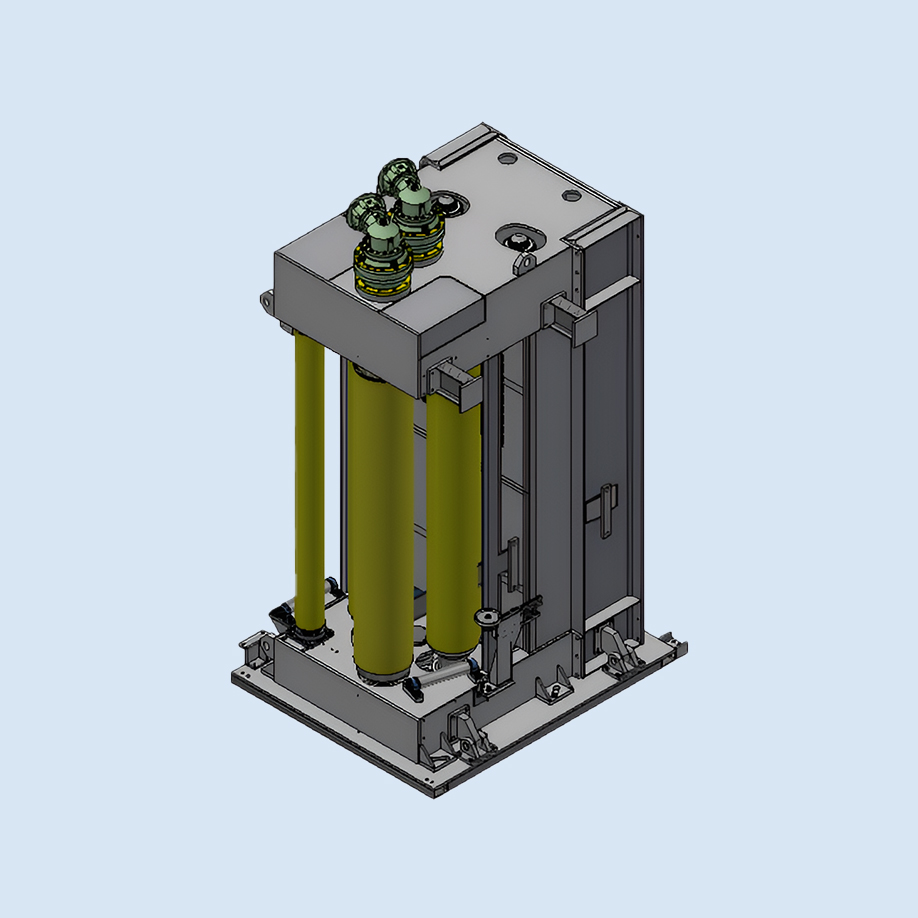

Vertical Plate Bending Machine SHIRV 2000×16 Duplex

• capacity radius: 12000 mm

• max thickness: 10 mm Duplex / LDX Duplex

• max thickness: 16 mm Carbon Steel S355

• max plate height: 2000 mm

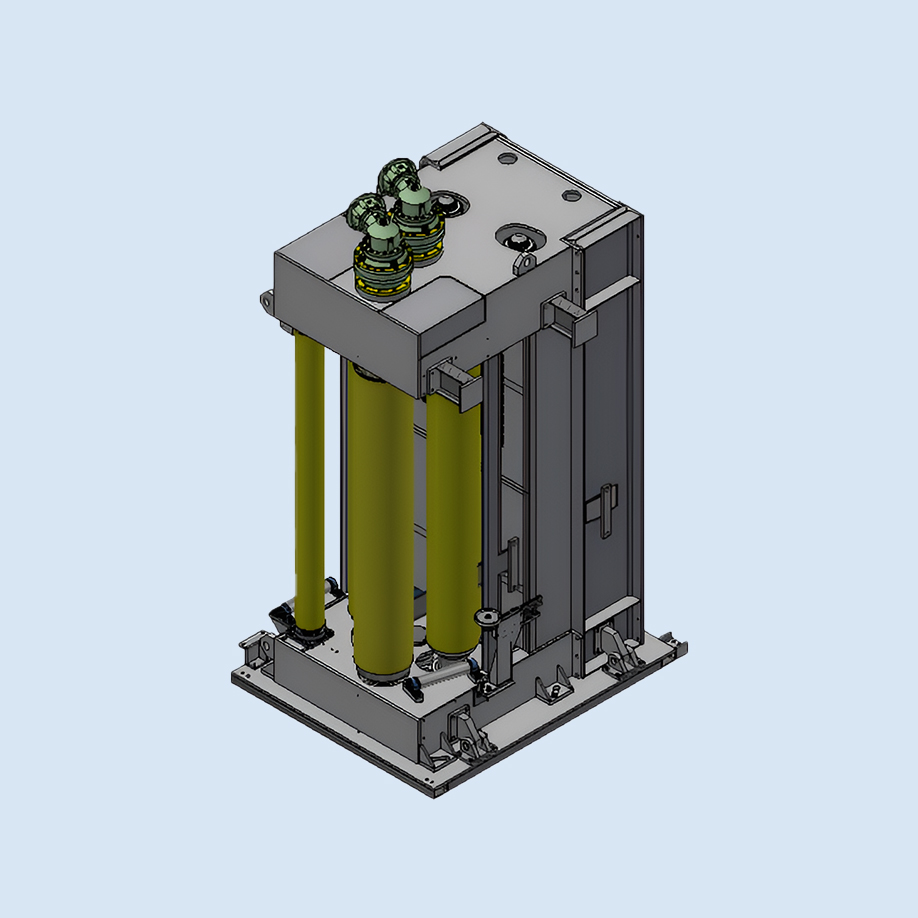

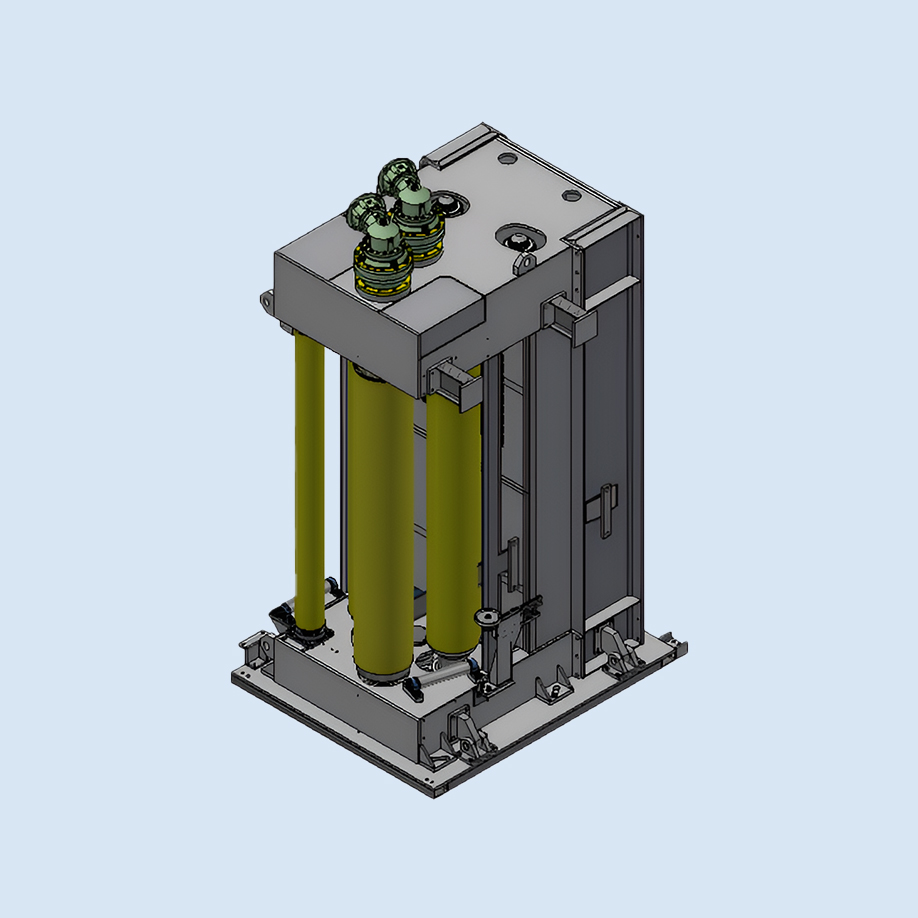

Decoiler

• power coil holder 2000 x 10 mm

• max height: 2000 mm

• max coil weight 25 T

• hydraulic swing insert arm for coil feeder

• min thickness: 2 mm

• max thickness: 10 mm

• material: Stainless Steel and Carbon Steel