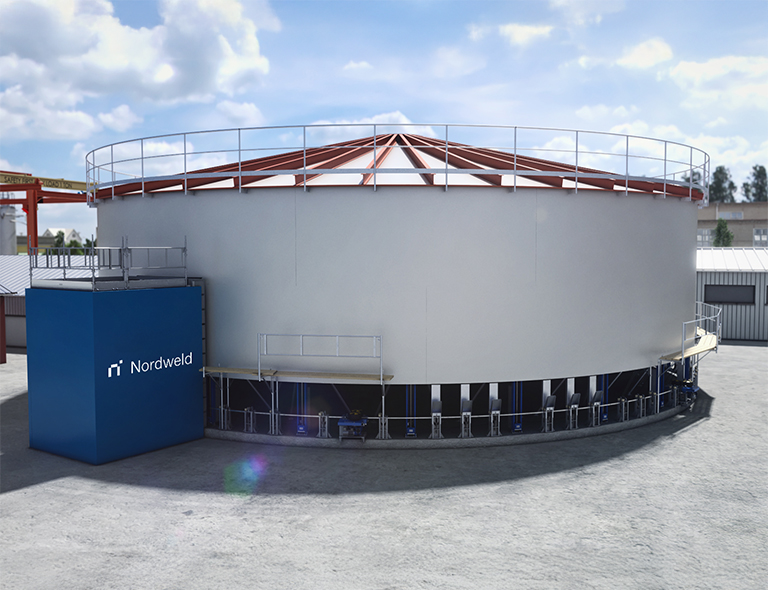

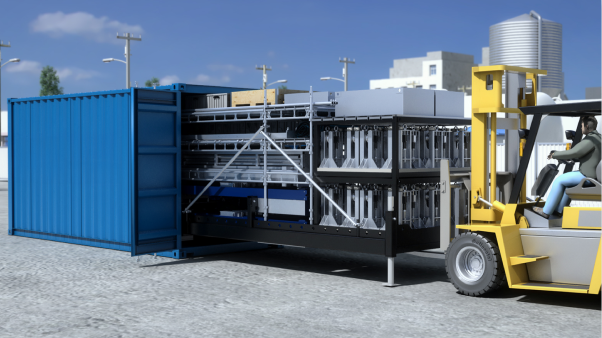

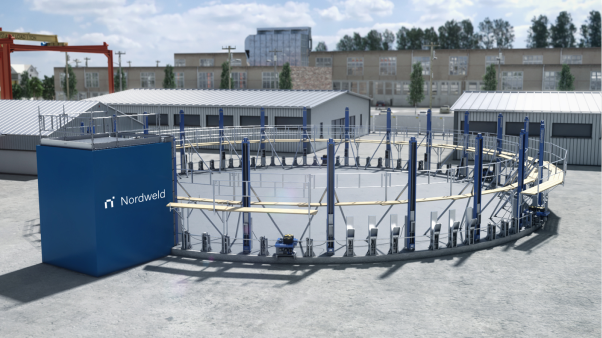

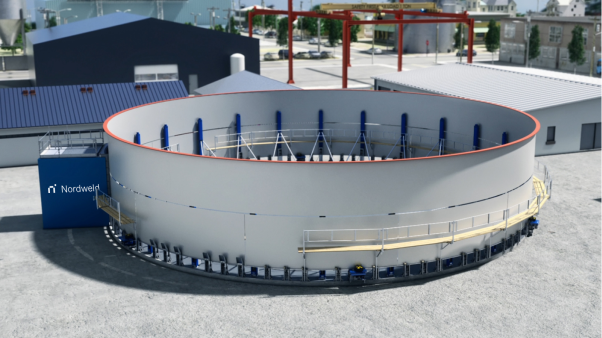

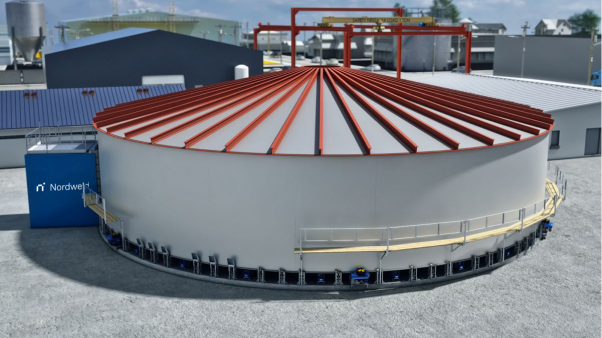

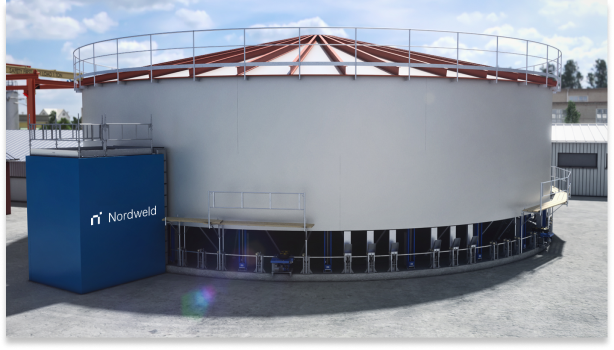

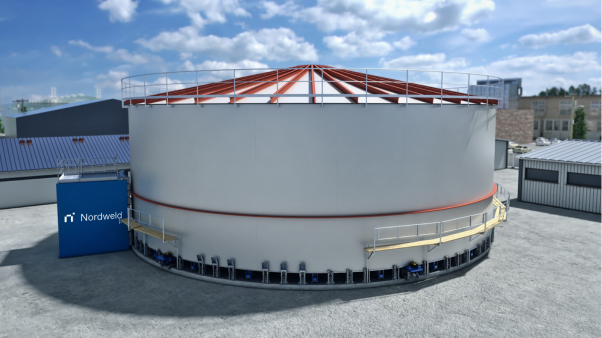

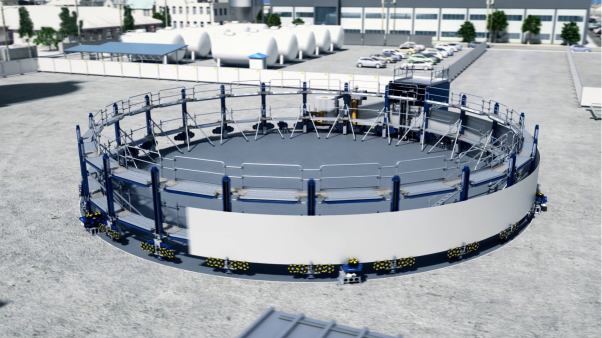

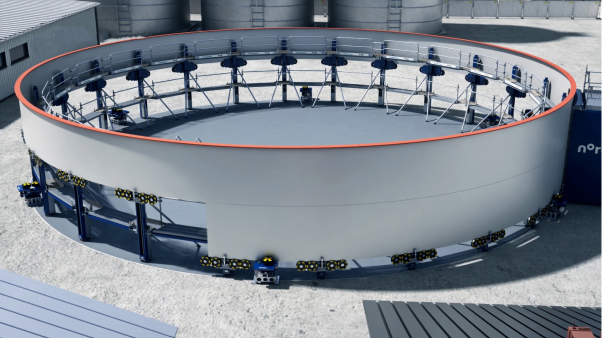

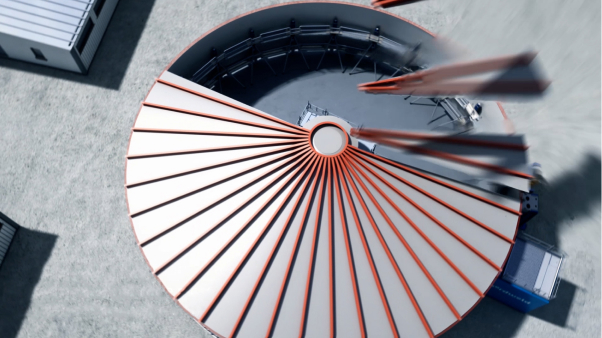

Nordweld’s Tank Building System – combining an advanced lifting system and rotation system – is designed for companies involved in the construction of aboveground welded steel storage tanks. With more than 30 years of experience, we understand the challenges faced by tank manufacturers and contractors, helping them deliver safe, high-quality tanks on time and at competitive costs.

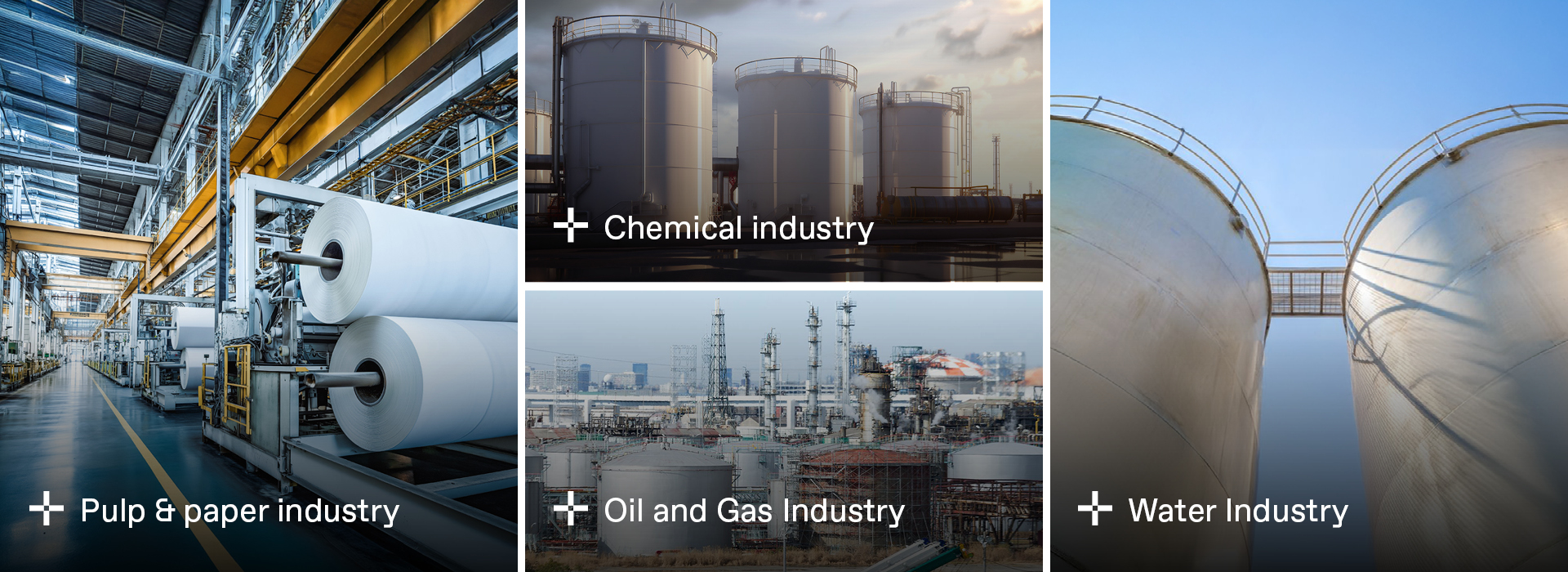

Our system supports the construction of storage tanks with diameters from 8 to 50 meters and a weight of up to 700 tons, making it an efficient solution for a wide range of industries such as oil & gas, LNG, biogas and fermentation, chemical, water, pulp & paper, food & beverage, brewing, and nuclear power.