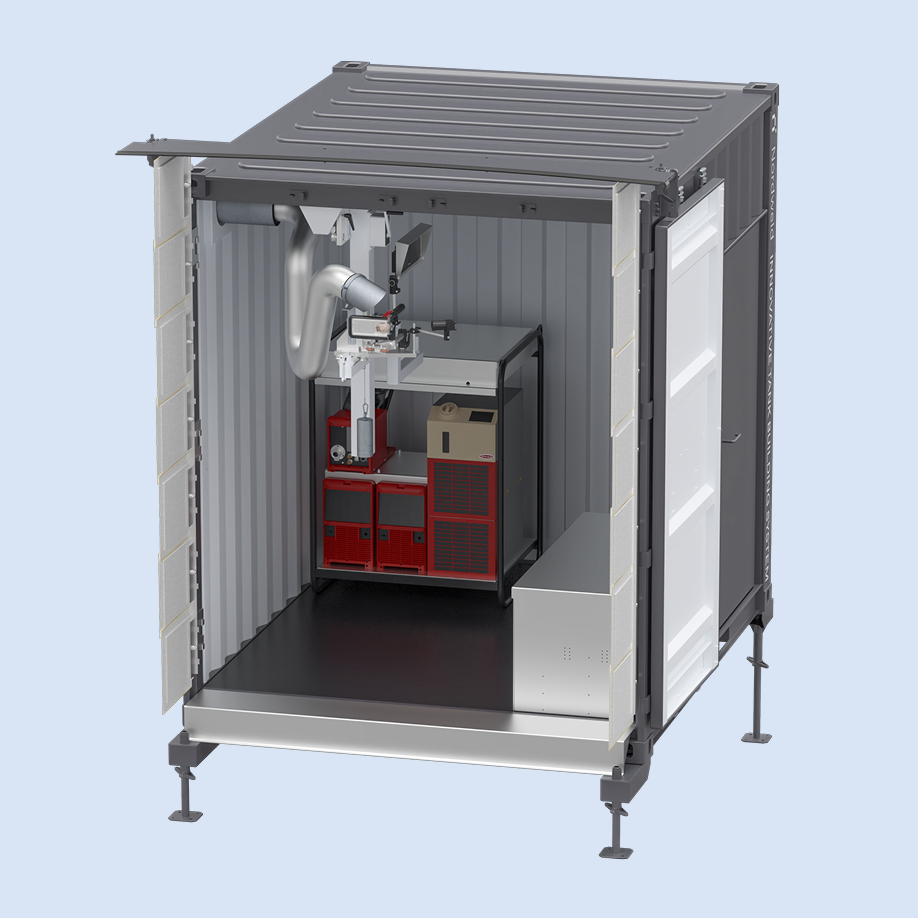

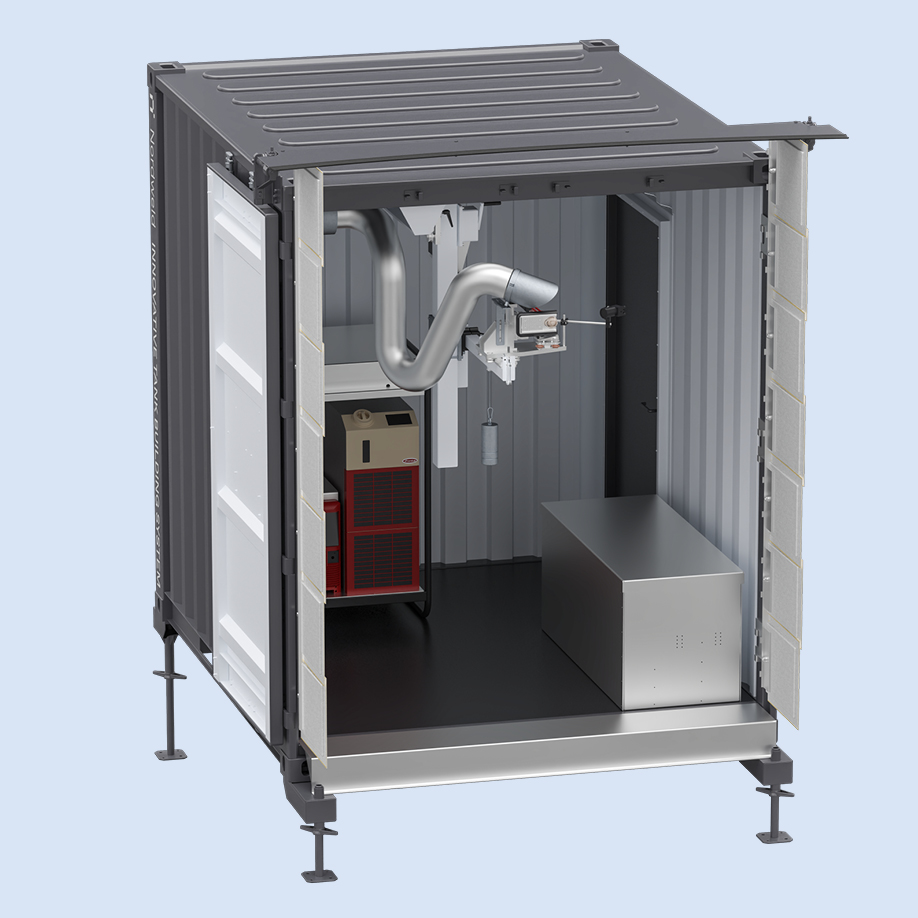

Automated welding station for circumferential tank welds

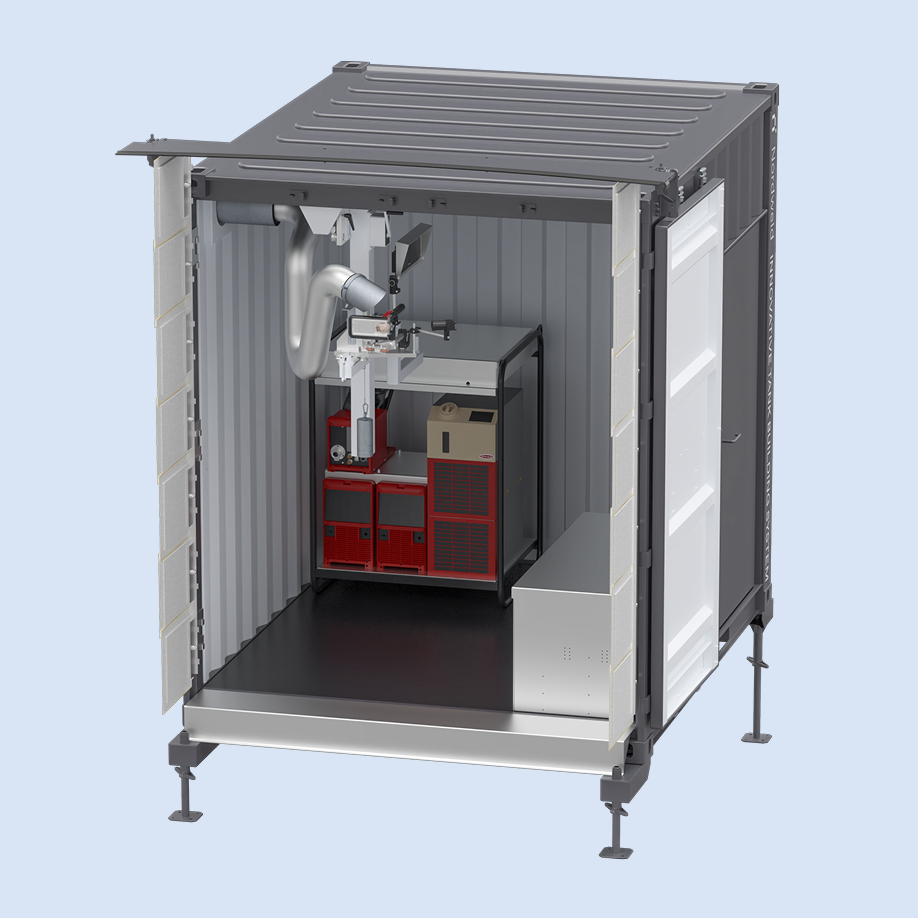

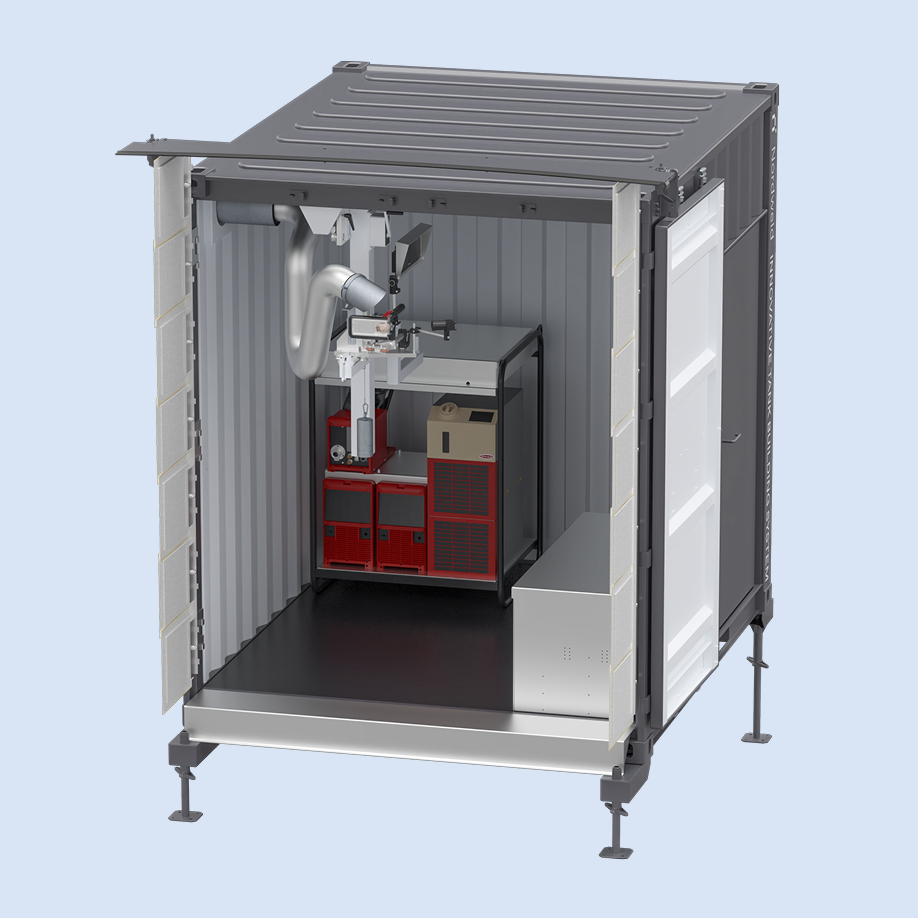

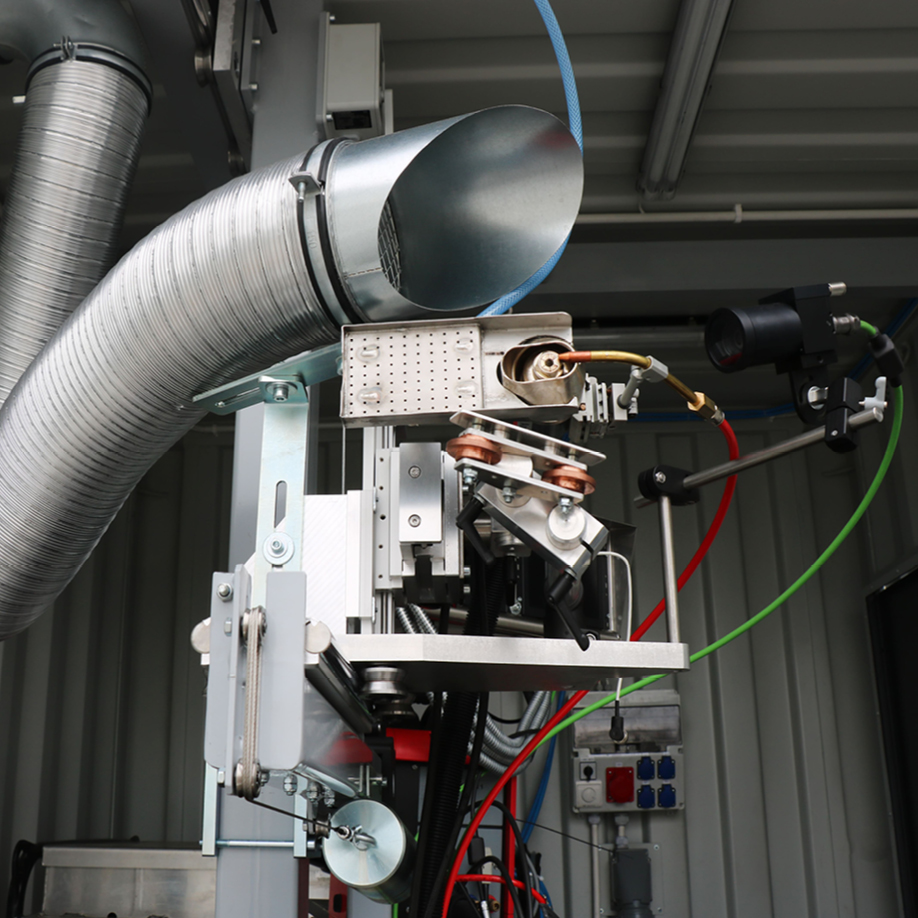

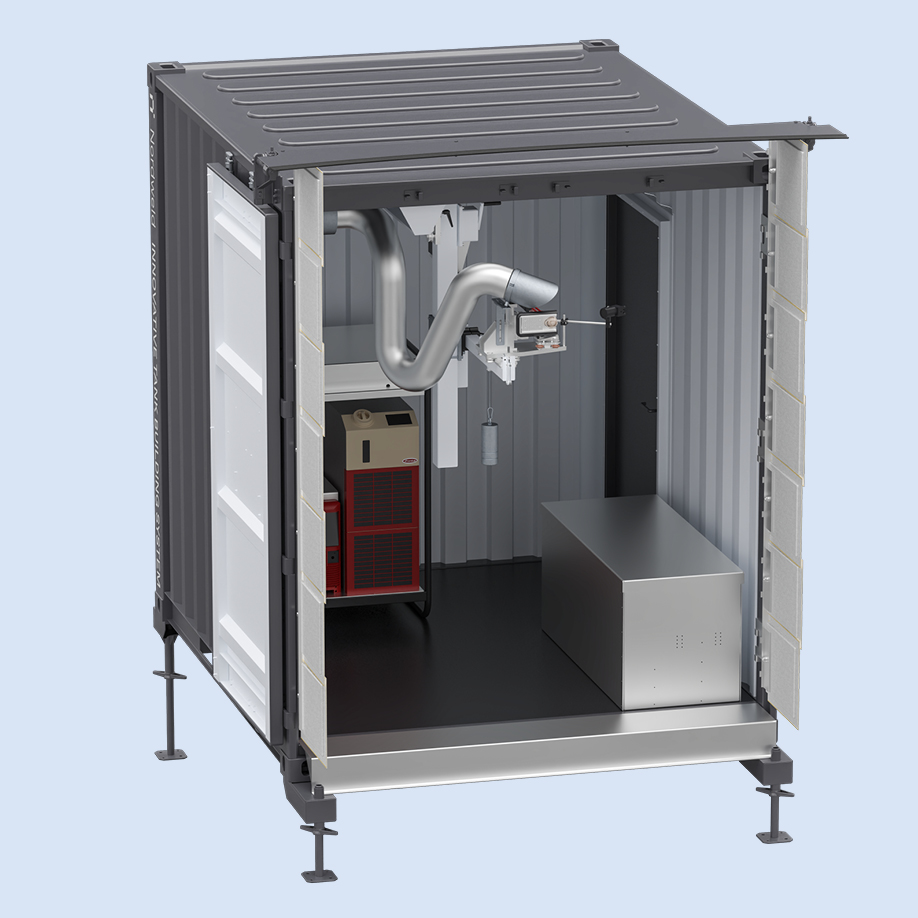

Dedicated welding container designed for performing high-quality circumferential welds on cylindrical tanks. All necessary welding components—including the power source, torch guiding system, control unit, and supporting accessories—are fully integrated within the container, ensuring mobility, quick deployment, and operational readiness.

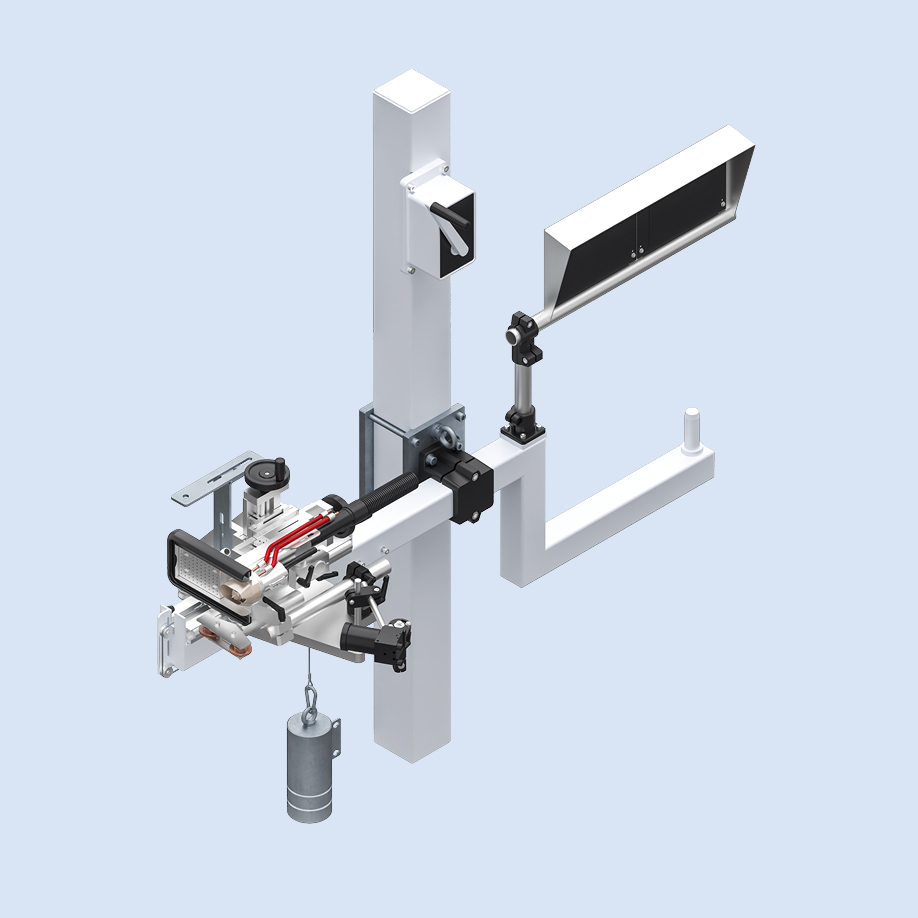

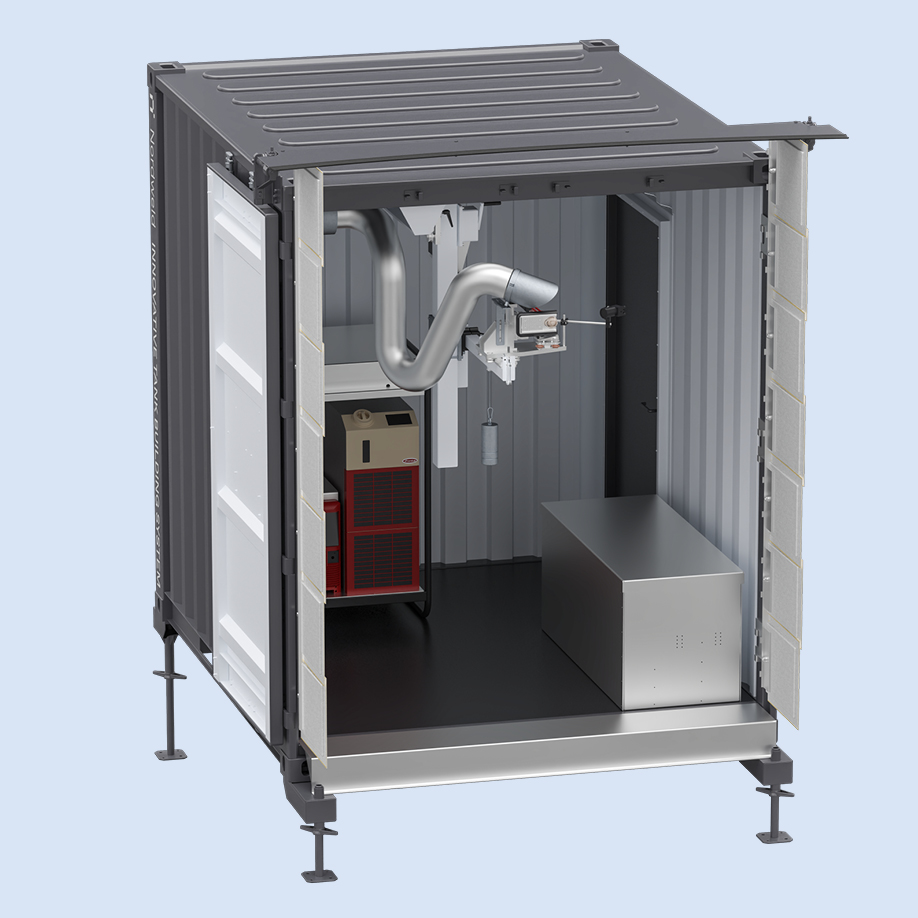

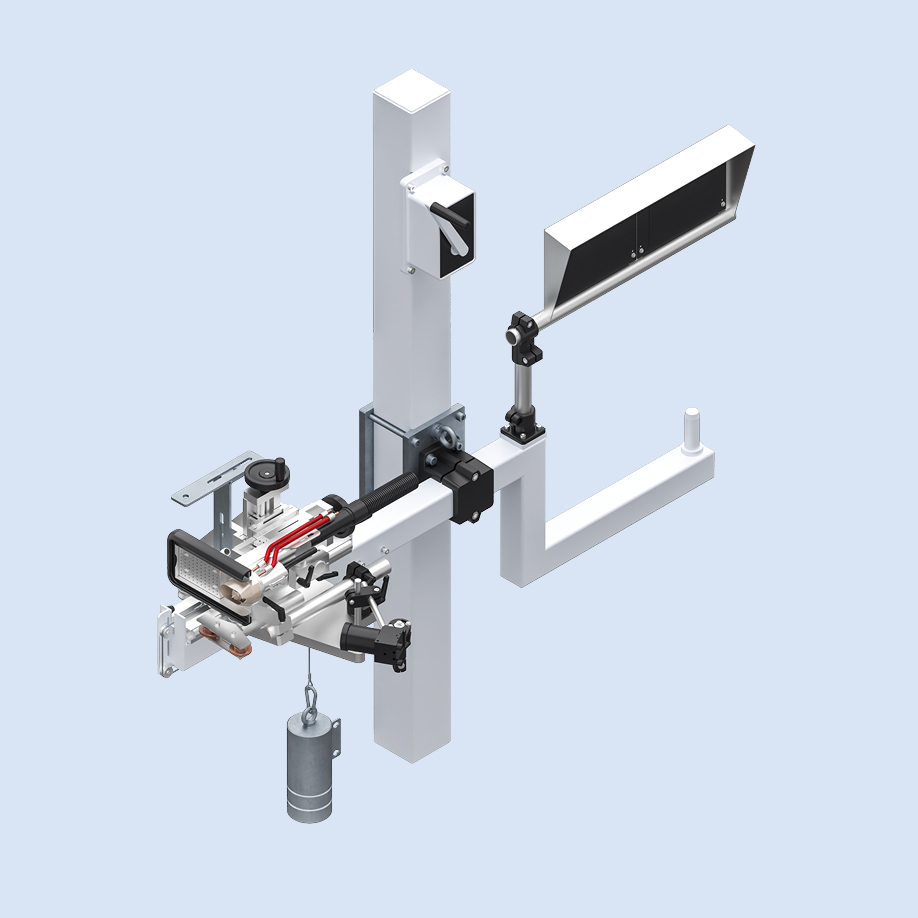

The container also features an industrial camera system with real-time monitoring, allowing for continuous visual supervision of the welding process via display screens.

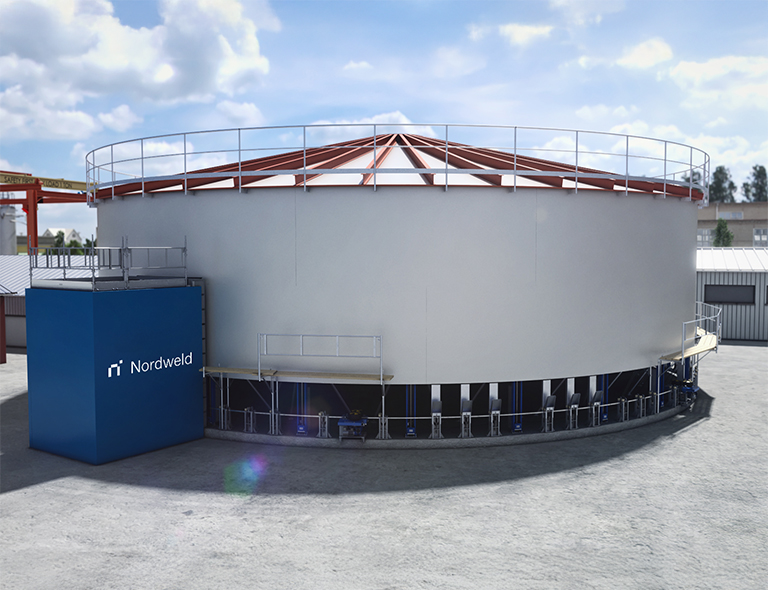

During operation, the container remains fixed in position relative to the tank, while the tank rotates using our advanced tank rotation system. The welding machine remains stationary, delivering a continuous and consistent weld as the tank turns.

Ask for an offer

Key advantages:

- Fully integrated workstation – All essential welding equipment is housed within the container, eliminating the need for a separate welding setup and significantly reducing preparation time.

- Process stability and repeatability – The stationary welding setup ensures precise calibration and consistently high-quality welds.

- Remote monitoring and supervision – An integrated camera and monitor system allows operators to supervise the weld remotely, enhancing quality control and reducing the need for direct observation through a welding mask.

- Optimized logistics – The compact, self-contained container is easily transportable, enabling efficient relocation to various job sites.

- Improved safety and ergonomics – Operators work in a controlled environment with convenient access to controls. The camera system reduces exposure to welding hazards and improves working comfort.

- Superior weld quality – Continuous rotation of the tank and stable torch positioning ensure smooth, uniform circumferential welds with excellent mechanical and visual properties.

- Weather protection for consistent weld quality – Welding is performed inside a fully enclosed container, shielding the process from wind, rain, and temperature fluctuations. This controlled environment ensures consistently high weld quality and stable working conditions, regardless of the season or external weather conditions.

The unique characteristics

Welding station configuration (model: 440-00 FRONIUS ARC TIG OR LINCOLN PLASMA):

- A complete welding station in a 10ft HC container

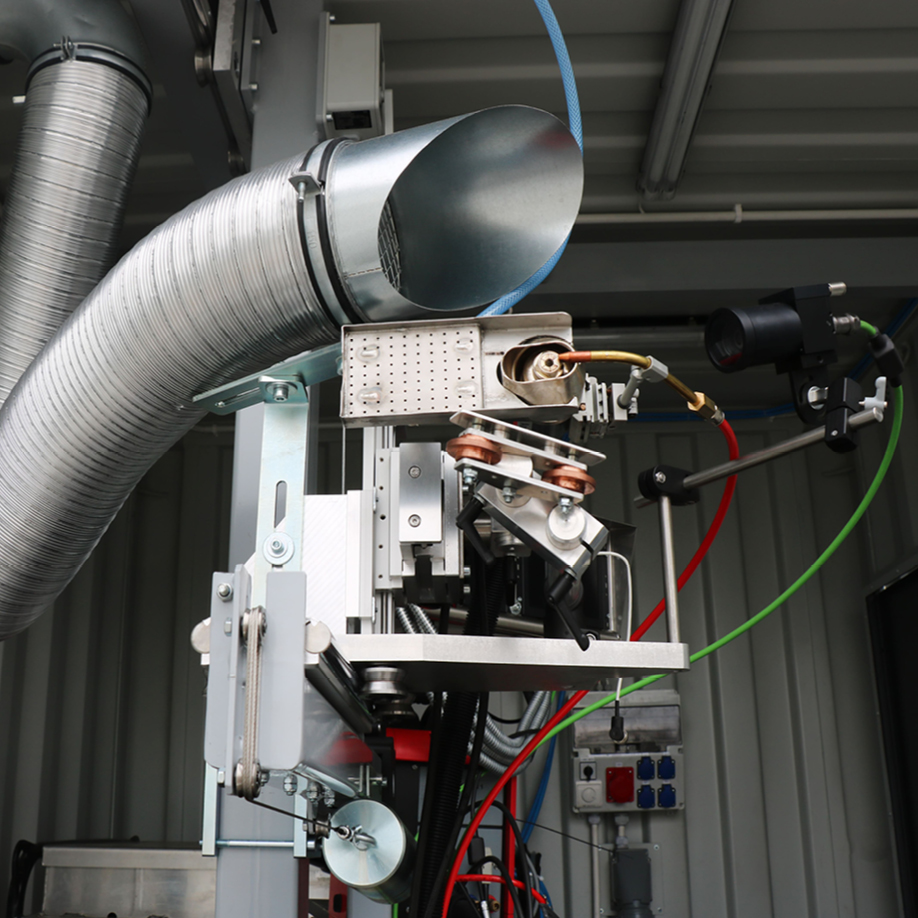

- Fronius Arc TIG assembled in a transport rack

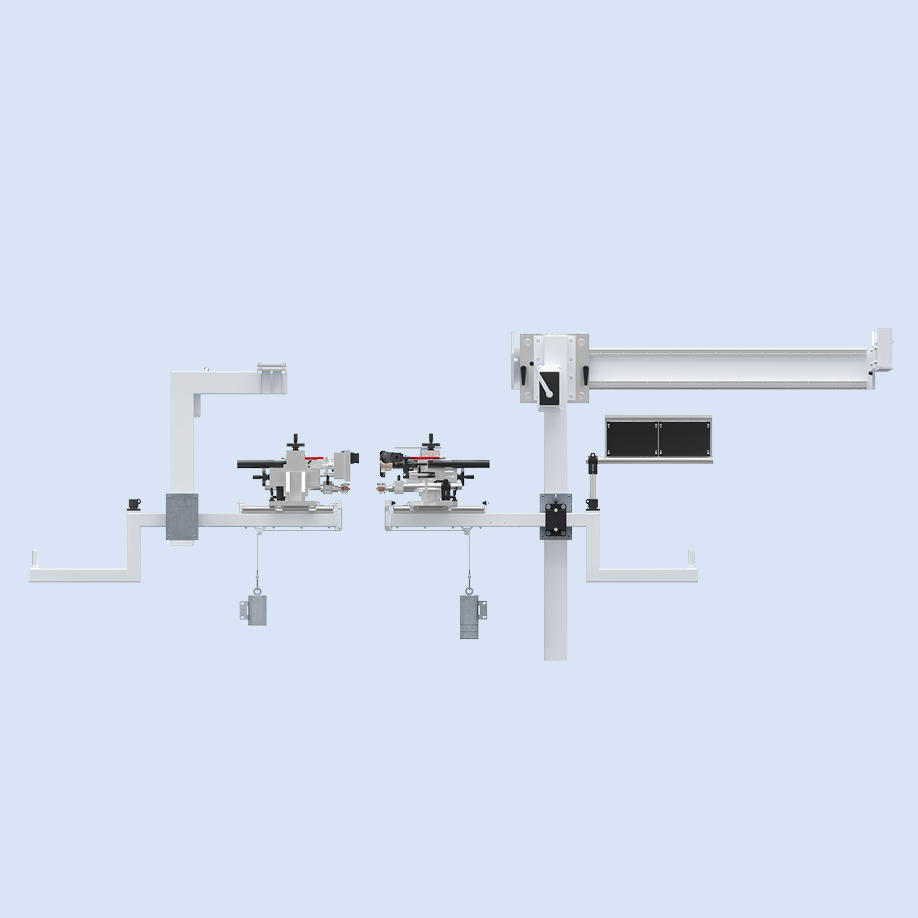

- Ability to weld from both outside and inside the tank

Product dimensions

- 1 x 10ft container with a 63A central, internal lightning, entrance door, shelfs, gas distribution system, wind protection.

- 1 x 63Amp cable 20m

- 2 x 500Amp Trans Tig

- 1 x water cooler

- 1 x Wire feeder incl. 5m hose package

- 1 x 1,5m hose pack incl TTW7200 Arc Tig torch

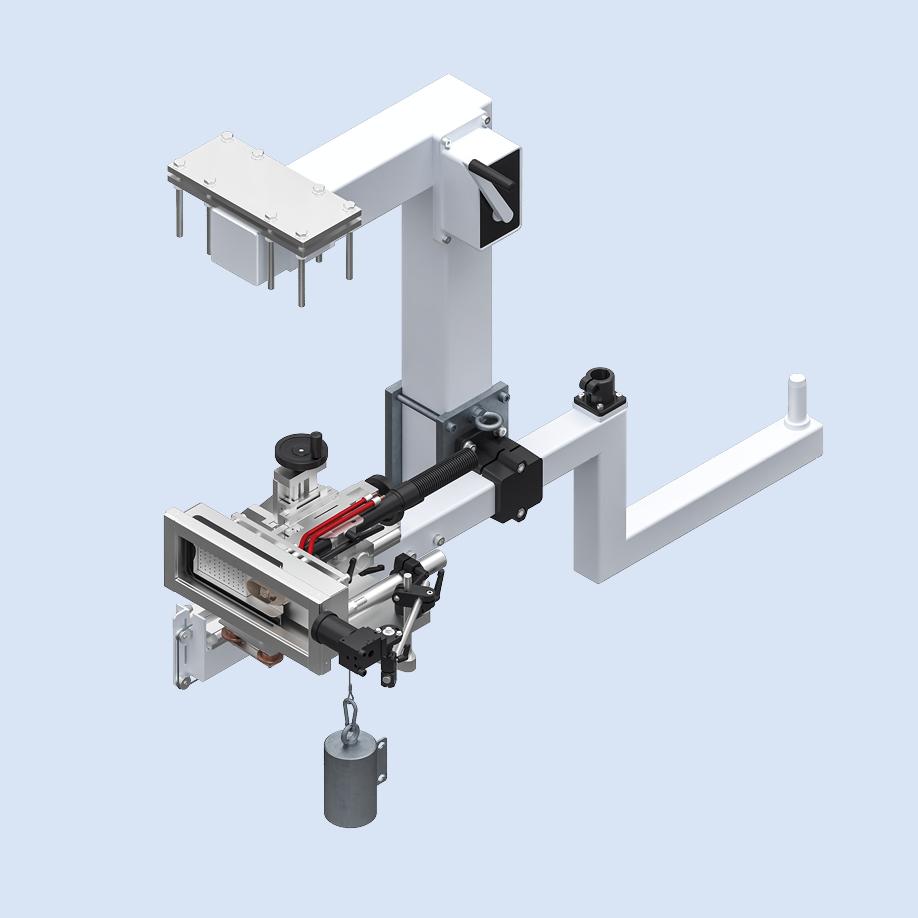

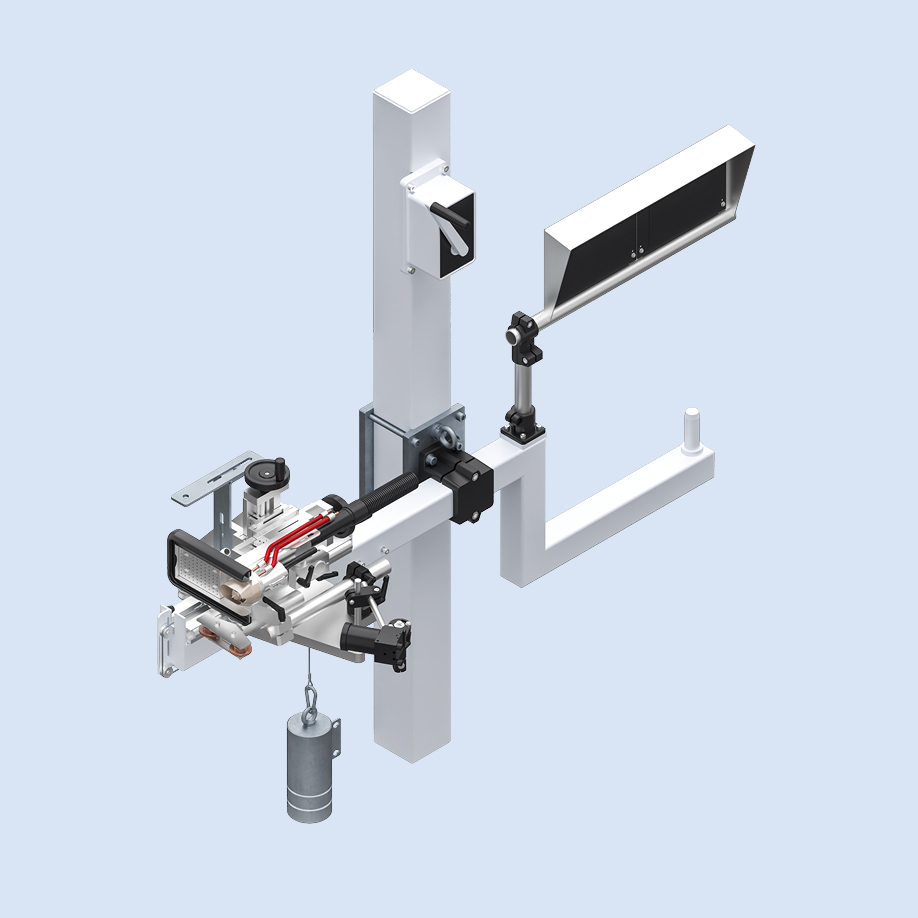

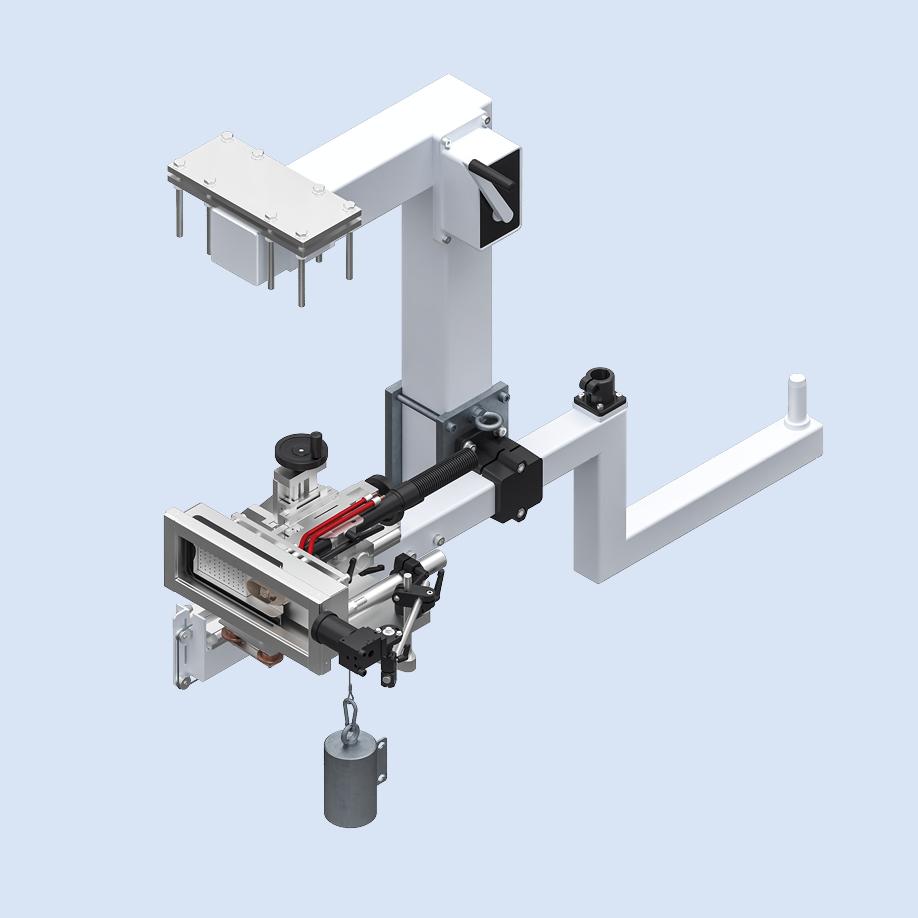

- 1 x welding torch set up with X-Y manual slides

- 1 x mechanical height sensor

- 1 x Bracket

- 1 x cooling unit for purge gas system

- 1 x purge gas system

- 1 x welding camera

- 1 x CNC camera for the purge gas side

- 2 x monitors

- All Cables

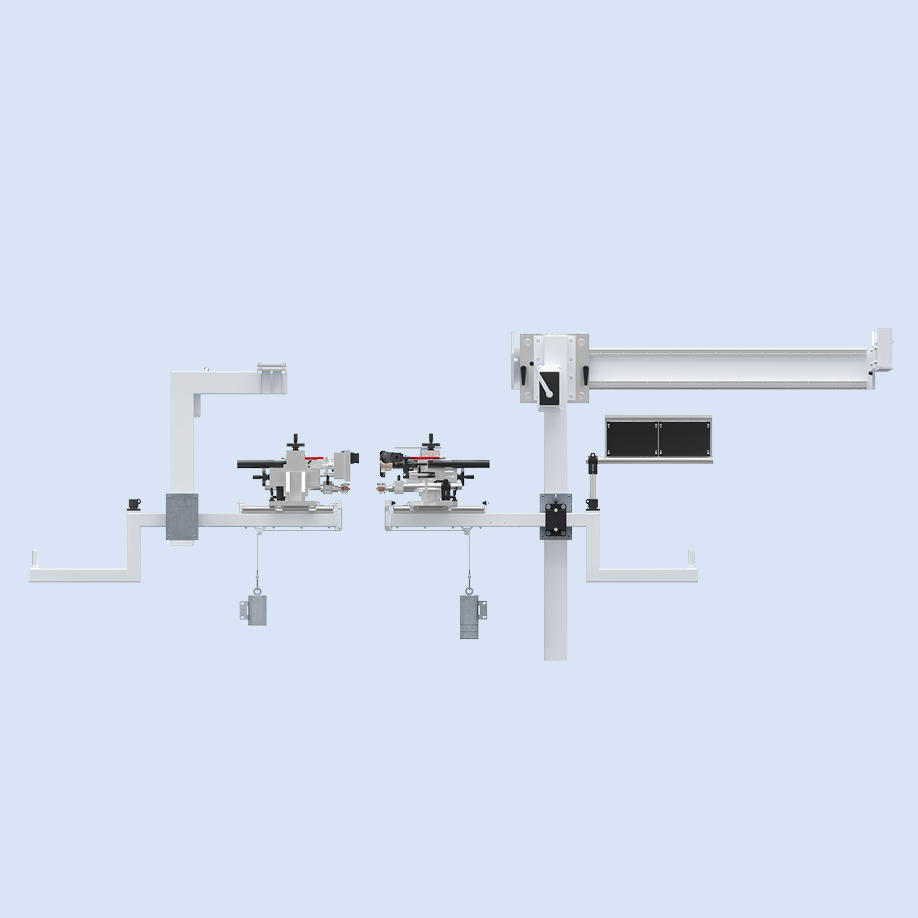

1 x 440-60 Internal unit for the purge gas or welding (same configuration as in the welding container)

1 x 100-70 Internal support beam between the lift jacks