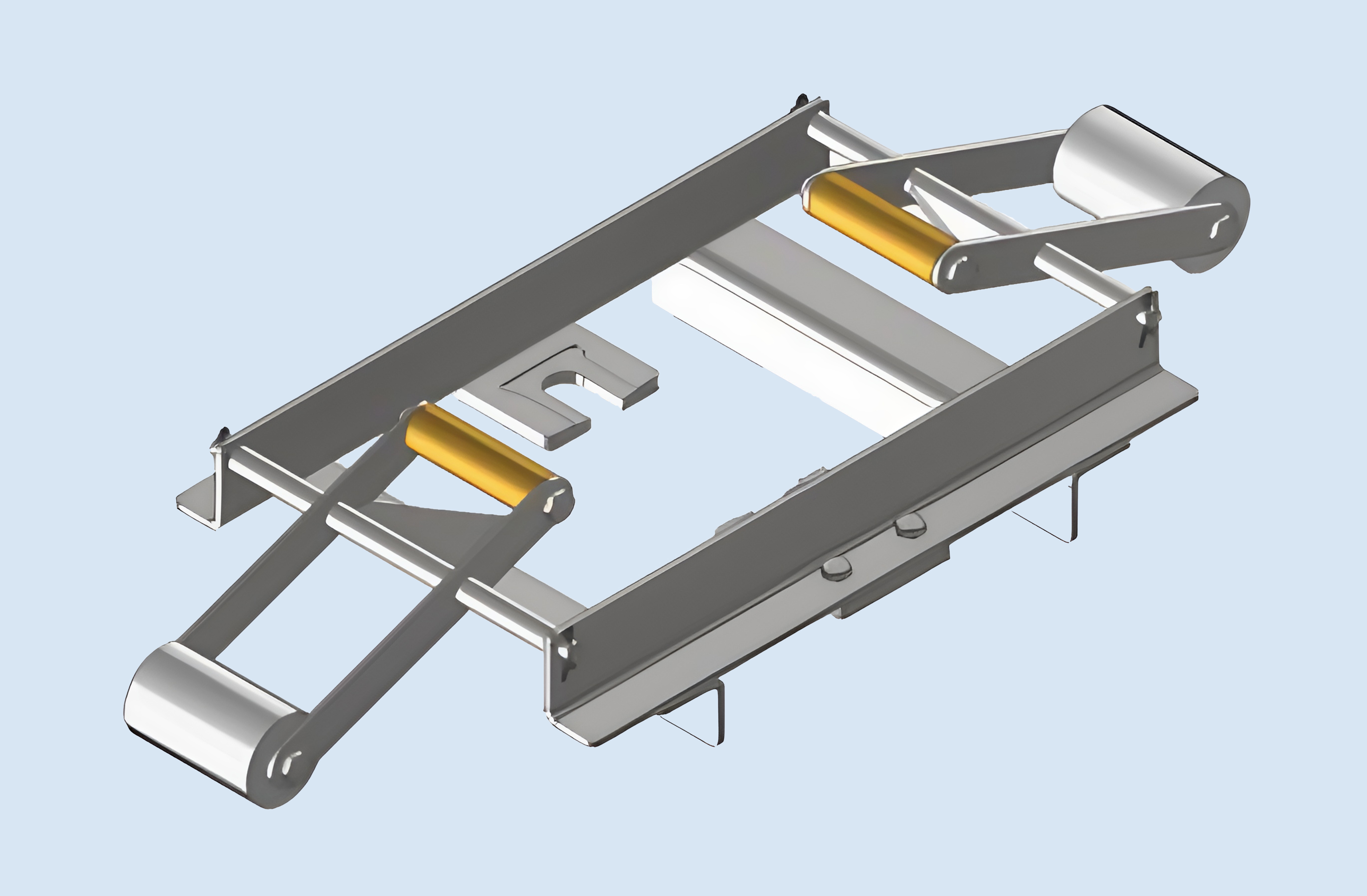

Roller Bed

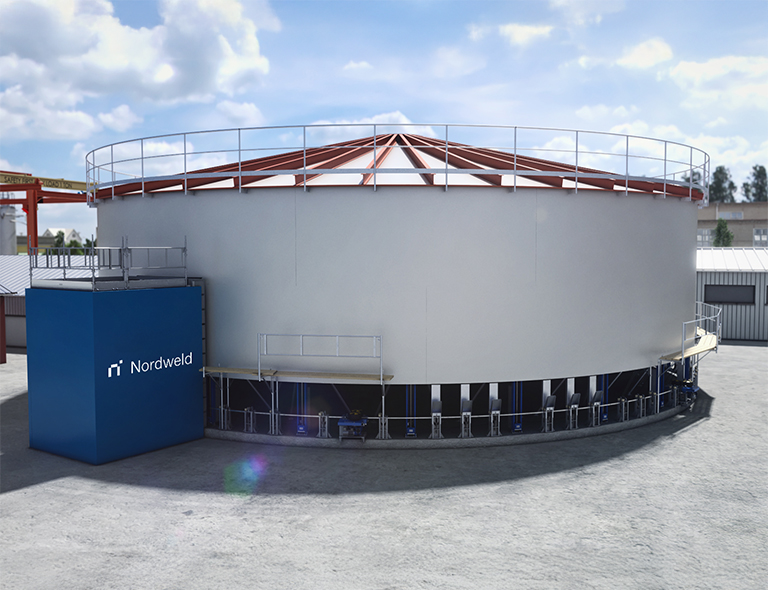

The Roller Beds are positioned around the perimeter of the tank bottom. A flat bar ring is placed on the wheels of the roller beds to distribute the load of the entire tank. As the tank rolls, it moves along with the support ring. Additionally, a special scaffolding pipe can be attached to the roller beds, allowing for the installation of scaffolding consoles to create exterior or interior working platforms.

Ask for an offer

The unique characteristics

The Roller Beds are positioned around the perimeter of the tank bottom. A flat bar ring is placed on the wheels of the roller beds to distribute the load of the entire tank. As the tank rolls, it moves along with the support ring. Additionally, a special scaffolding pipe can be attached to the roller beds, allowing for the installation of scaffolding consoles to create exterior or interior working platforms.

We offer:

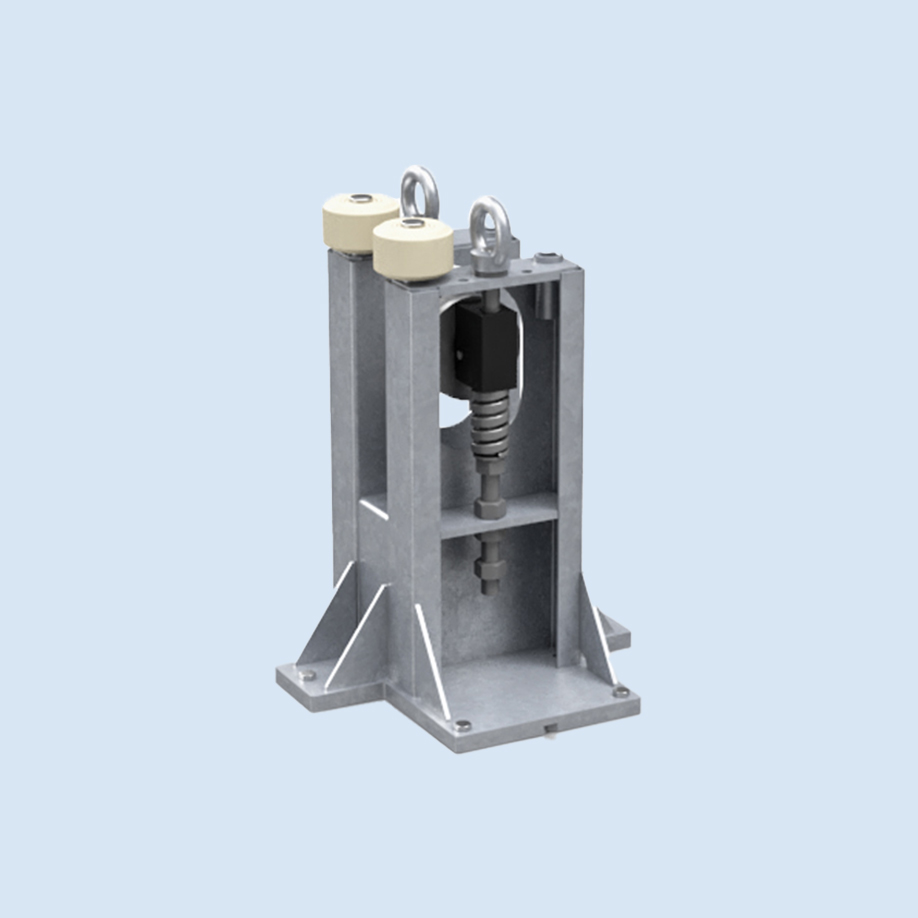

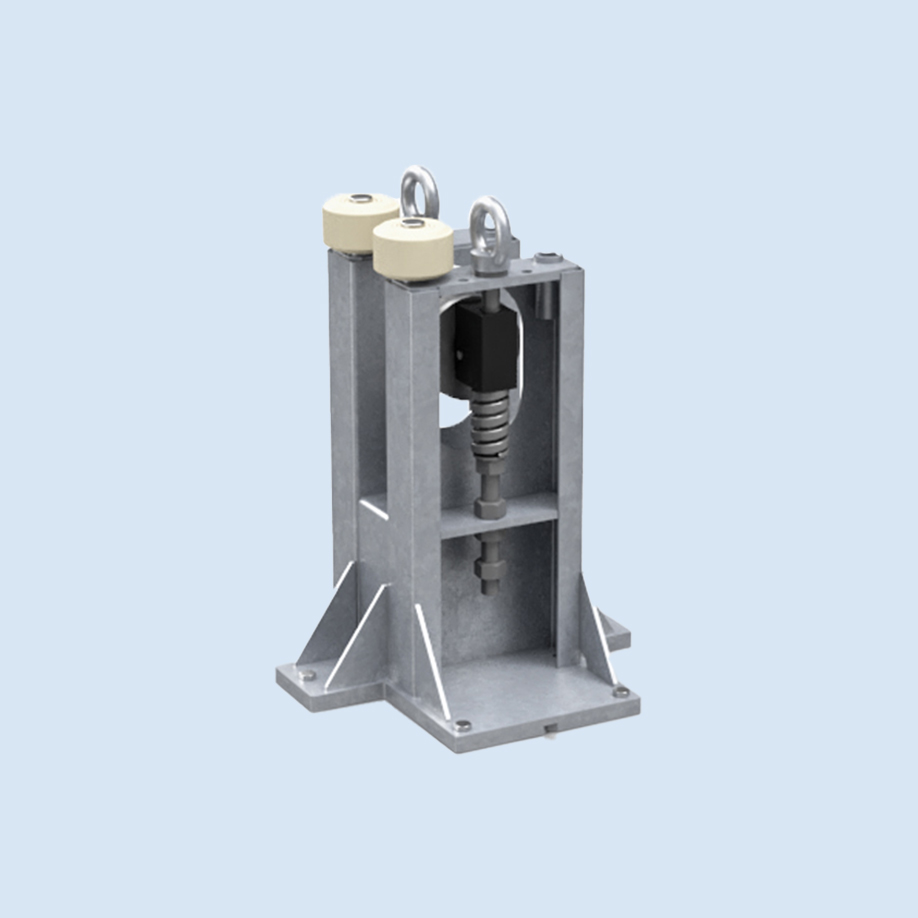

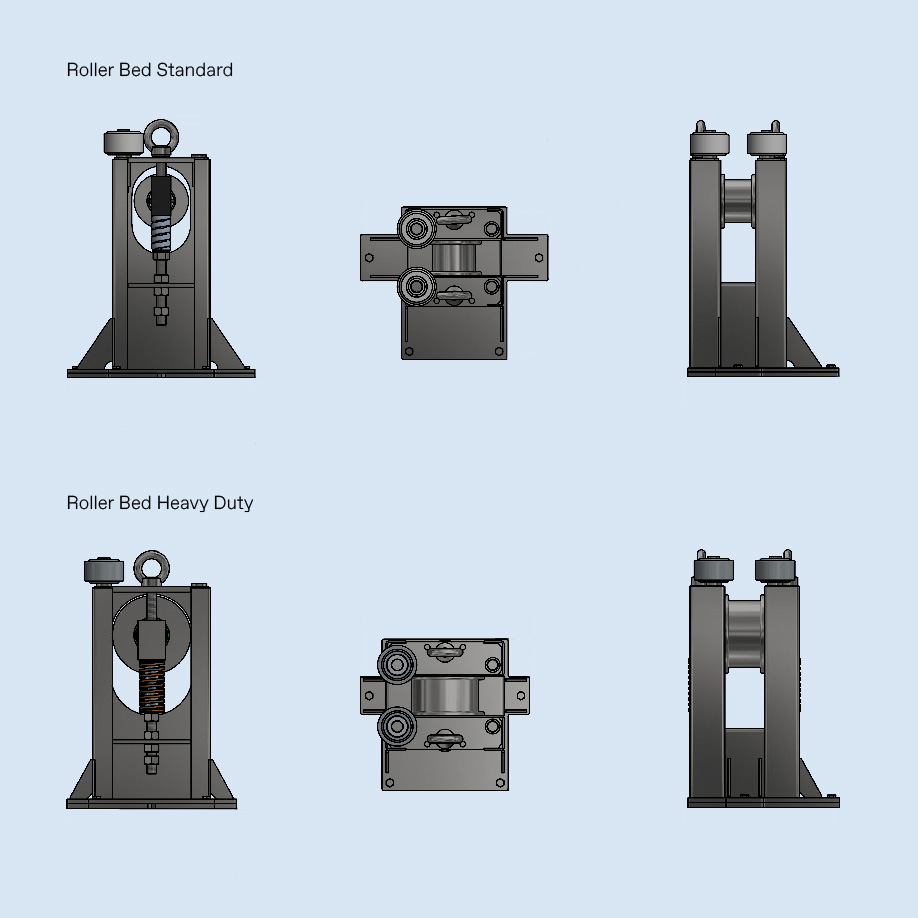

• Roller Bed Standard – max. load: 4T

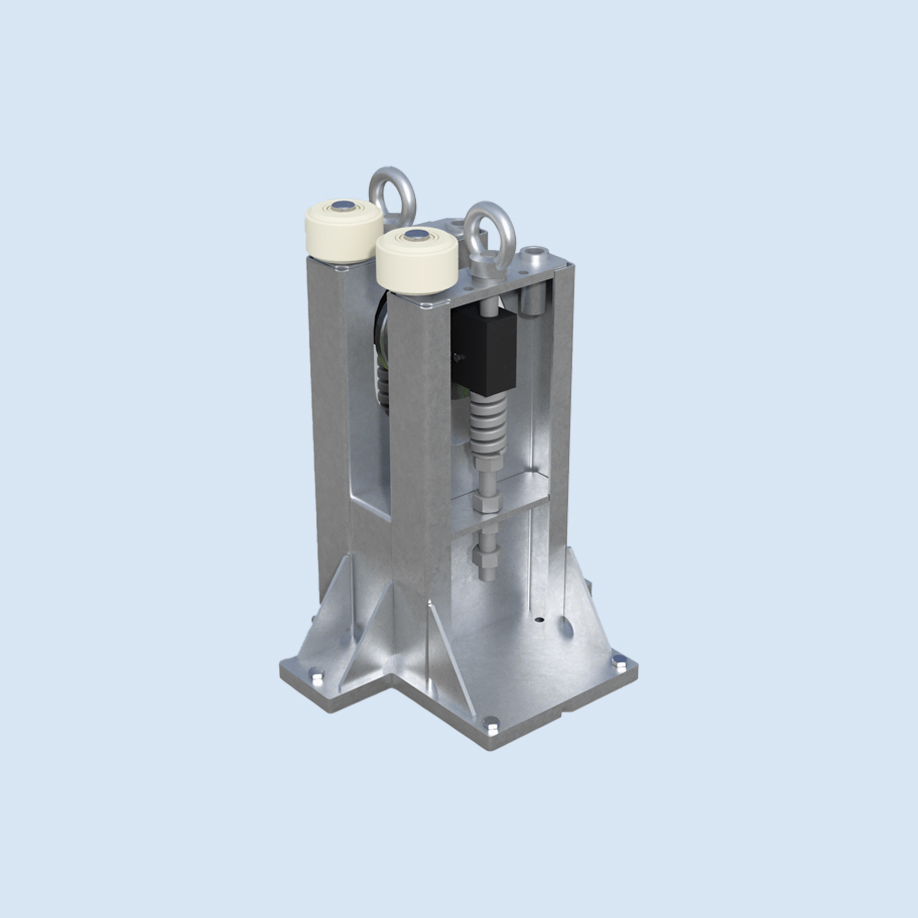

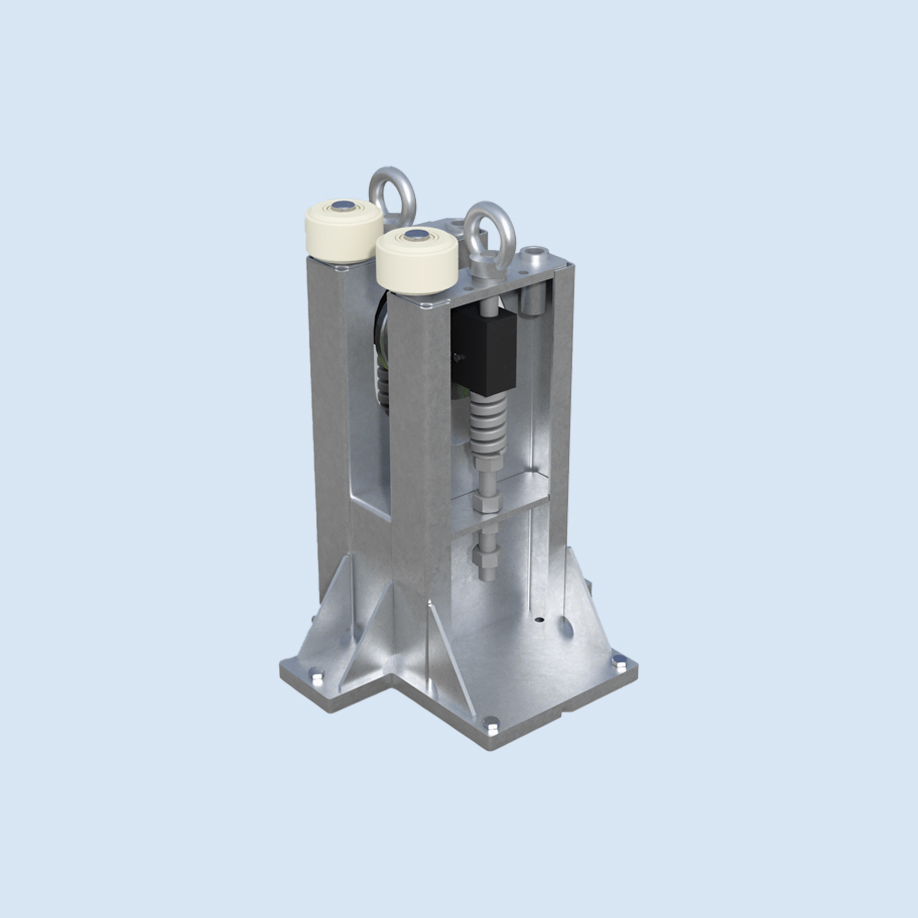

• Roller Bed Heavy Duty – max. load: 6T

Product dimensions

Dimensions of Roller Bed: 480 mm x 660 mm x 390 mm.

Dimensions of Roller Bed: 430 mm x 655 mm x 385 mm.

| Roller Bed Standard | Dimensions [mm] |

| Width | 480 |

| Height | 660 |

| Depth | 390 |

| Weight [ kg / lbs] | |

| kg | 60 |

| lbs | 132,27 |

| Roller Bed Heavy Duty | Dimensions [mm] |

| Width | 430 |

| Height | 655 |

| Depth | 385 |

| Weight [ kg / lbs] | |

| kg | 87 |

| lbs | 191,80 |

Documents