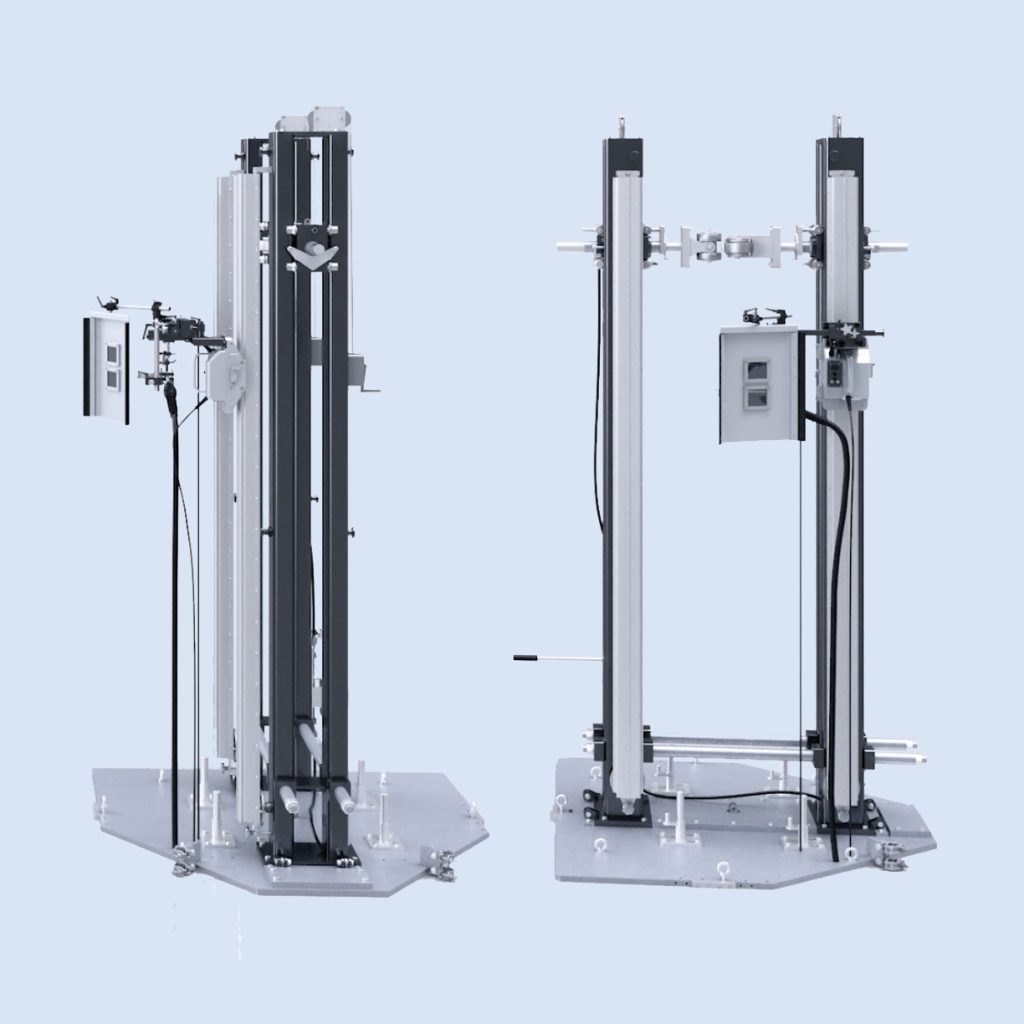

Tack Weld Stand

The horizontal joint is aligned as the tank rotates continuously. Tack welding is performed from a single location, making the process simple, fast, and cost-effective. When attaching stiffening rings to the tank wall, the stand can compress each ring segment securely against the tank wall.

Ask for an offer

Tack Weld configuration

The horizontal joint is aligned as the tank rotates continuously. Tack welding is performed from a single location, making the process simple, fast, and cost-effective. When attaching stiffening rings to the tank wall, the stand can compress each ring segment securely against the tank wall.

Weld configuration

The stand can be fitted with a rail track, allowing for the use of a welding tractor for mechanized vertical welding. This setup also facilitates mechanized circumferential welding. Additionally, with a special attachment, it enables the execution of fillet welds on stif-

fening rings.

Product dimensions

Dimensions of Tack Weld Stand: 1986 mm x 3761 mm x 1898 mm.

| Tack Weld Stand | Dimensions [mm] |

| Width | 1986 |

| Height | 3761 |

| Depth | 1898 |