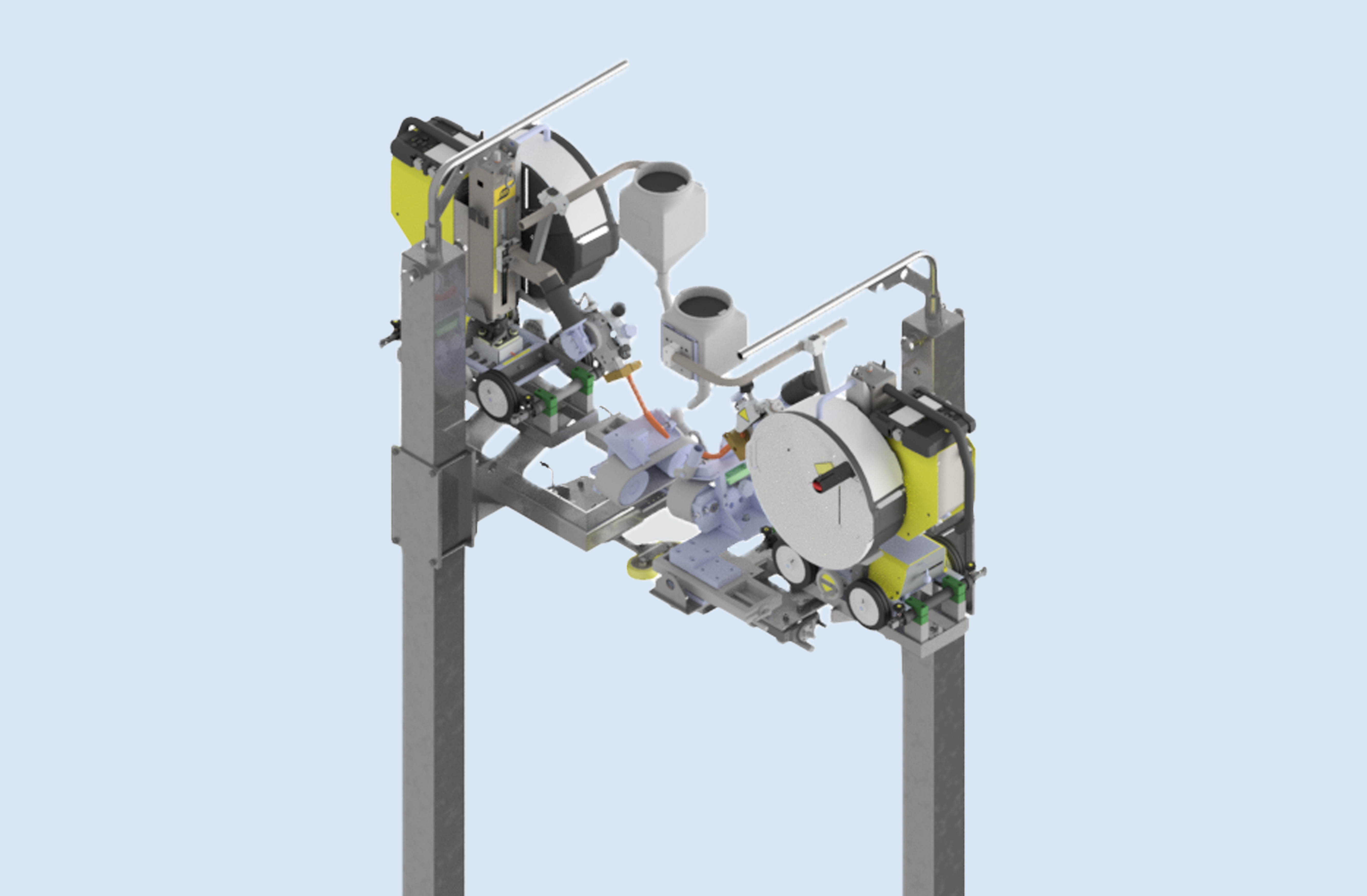

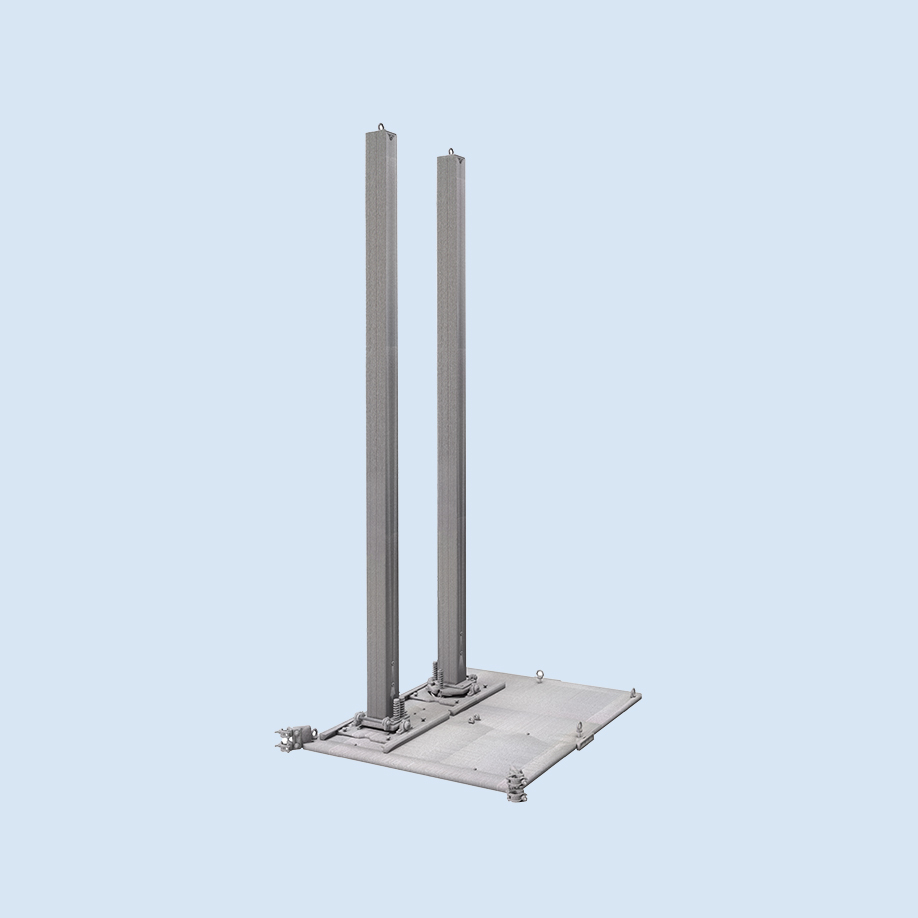

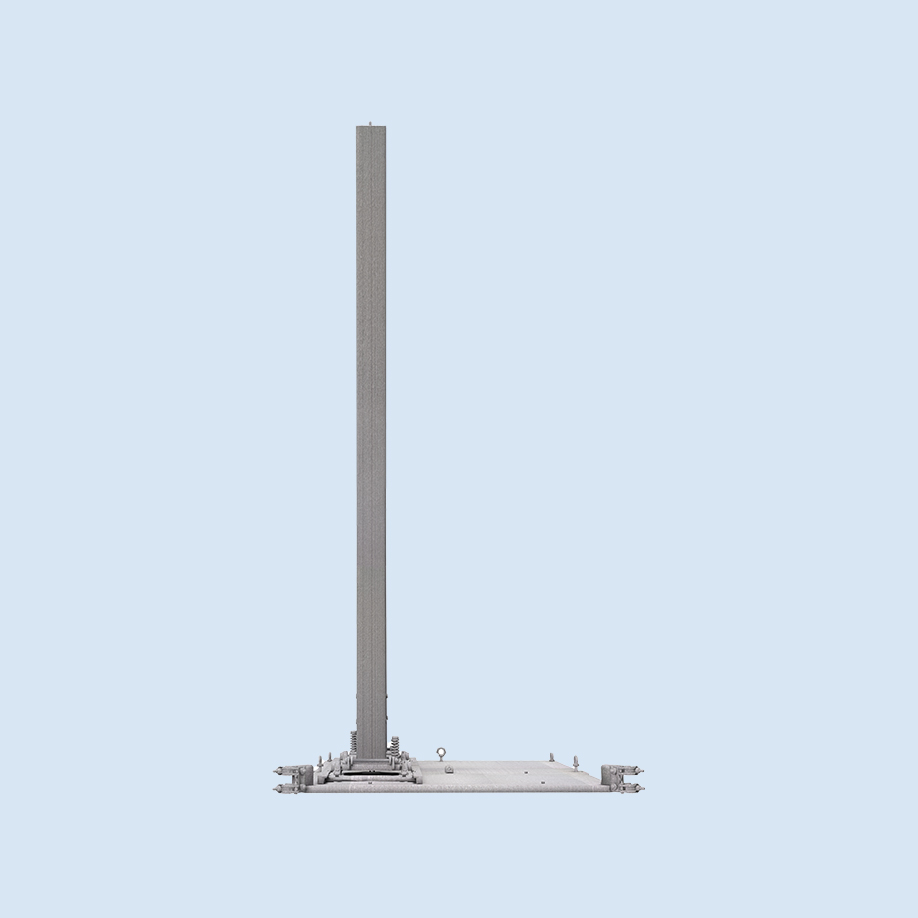

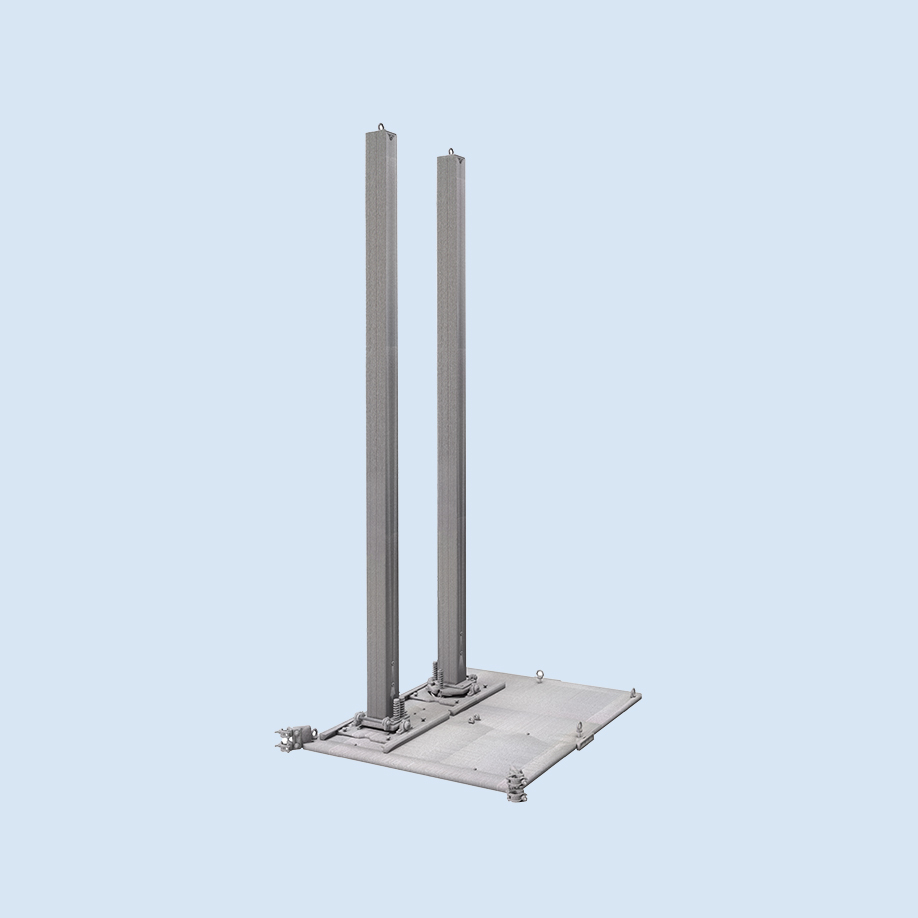

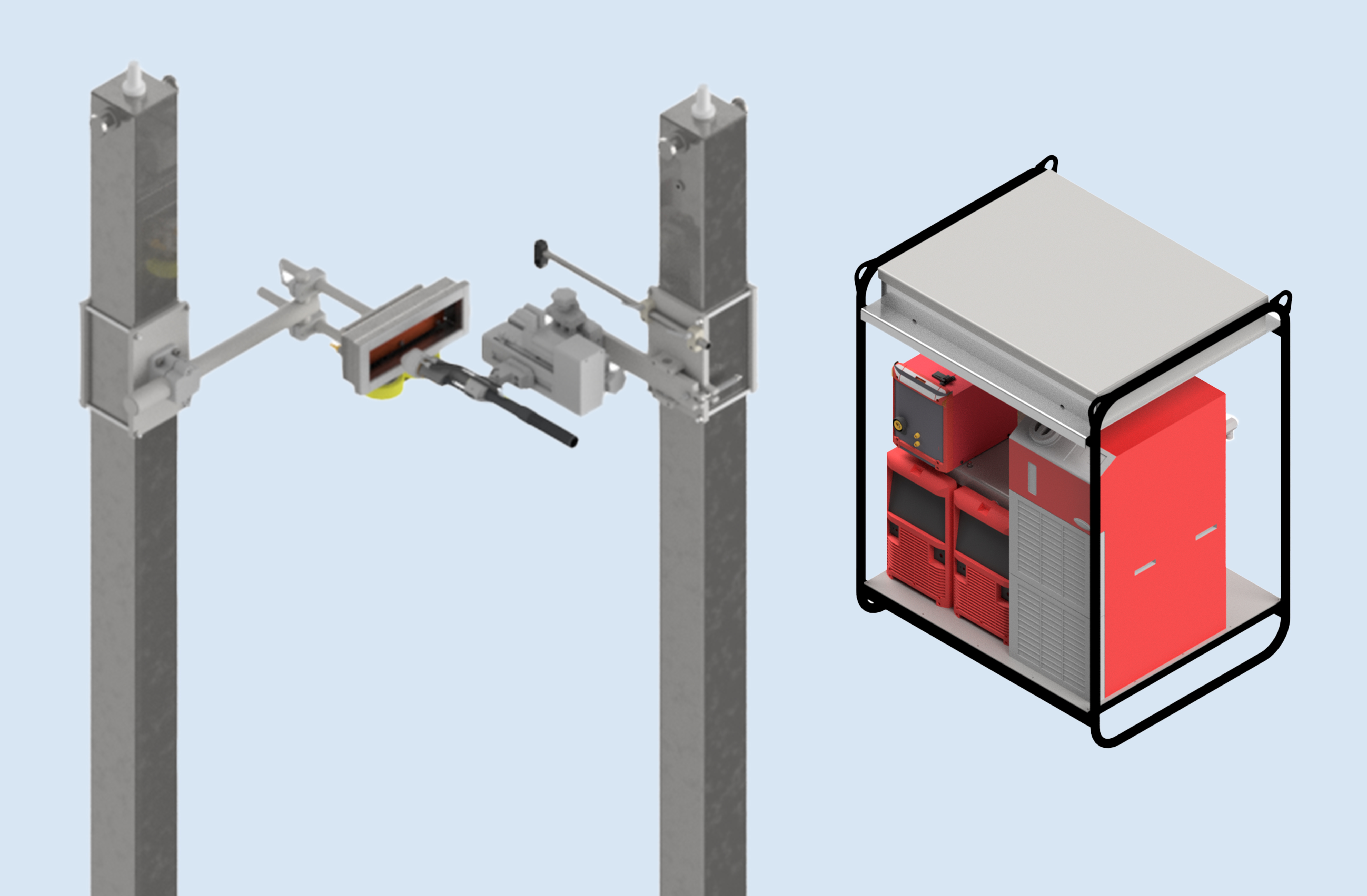

Weld Stand

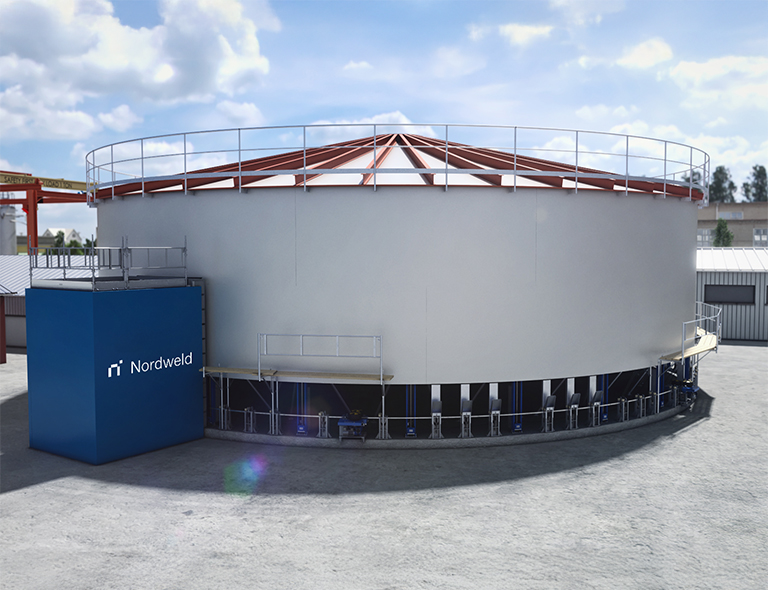

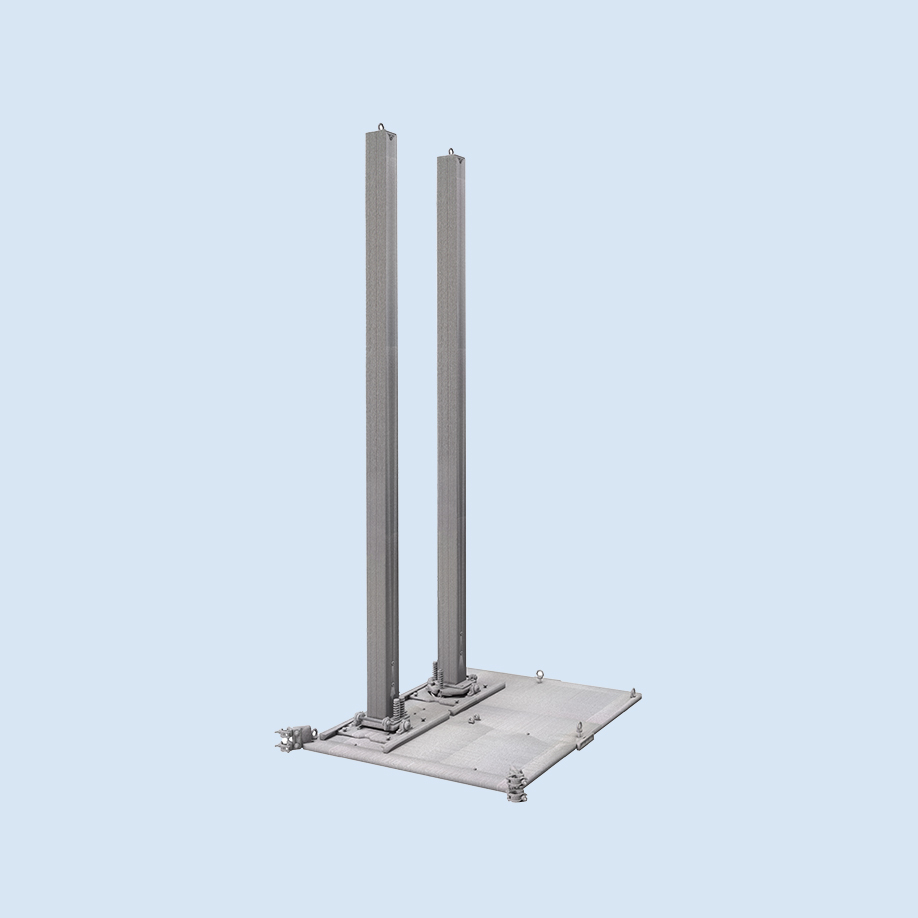

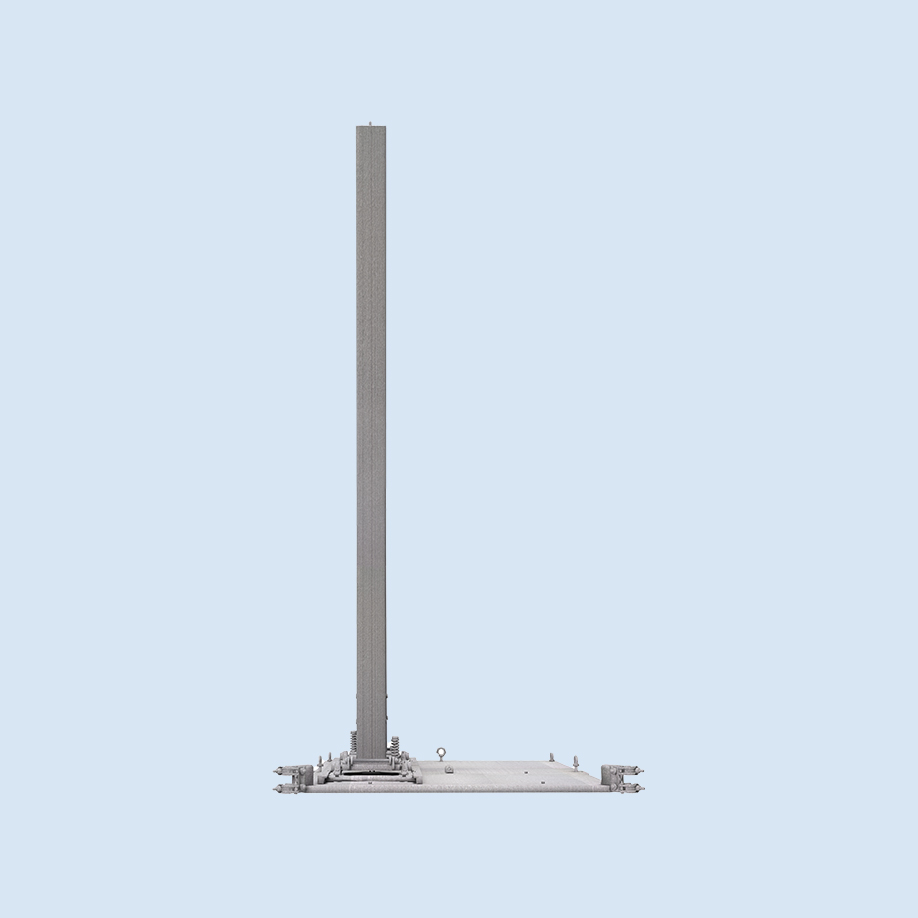

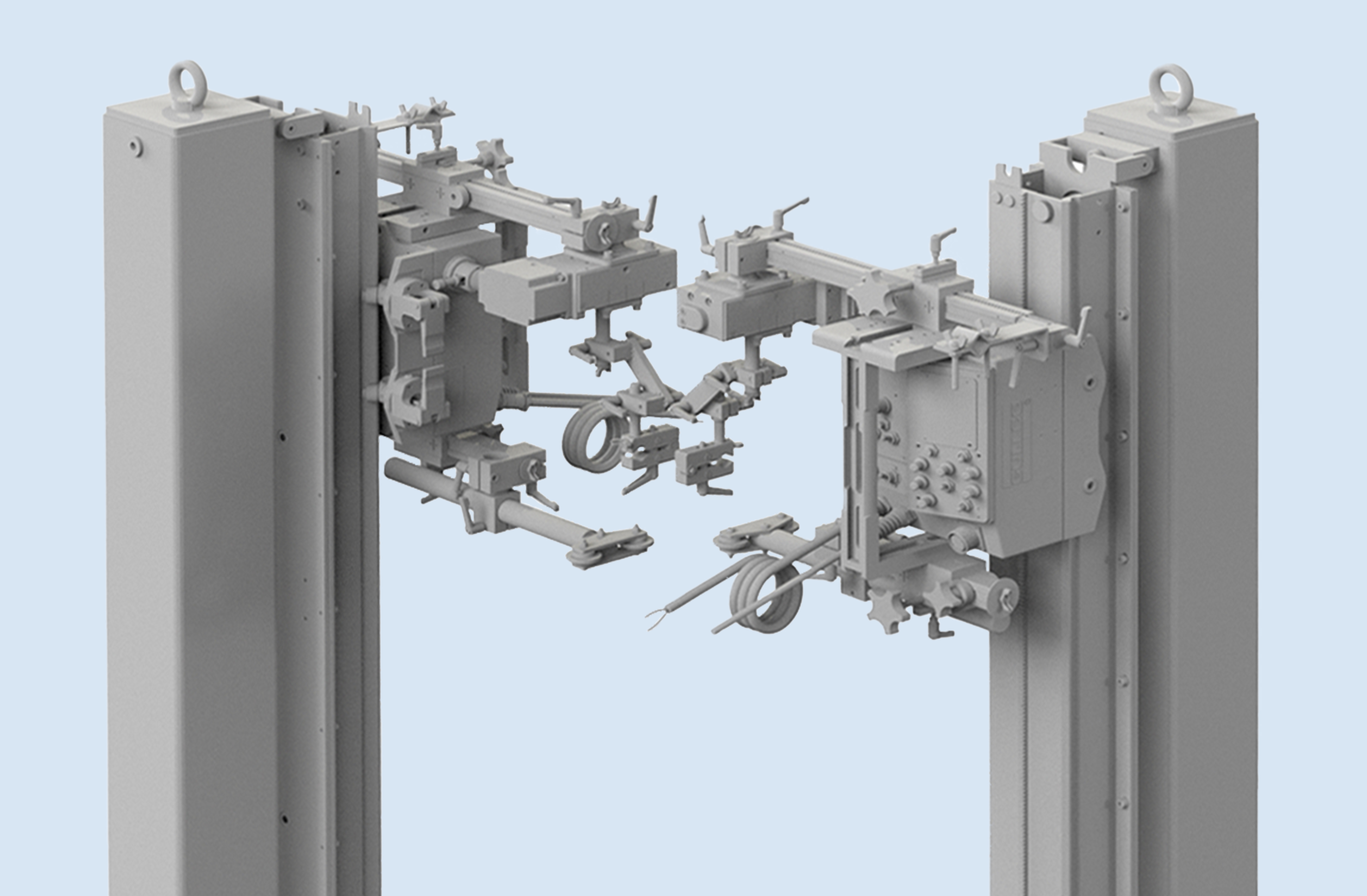

The Weld Stand supports various mechanized welding applications, including MIG/MAG, SAW, Plasma, and Arc TIG. It features a base plate and two spring-loaded columns that continuously move inward toward the shell, ensuring stable and precise welding.

Ask for an offer

The unique characteristics

The Weld Stand supports various mechanized welding applications, including MIG/MAG, SAW, Plasma, and Arc TIG. It features a base plate and two spring-loaded columns that continuously move inward toward the shell, ensuring stable and precise welding.

Product dimensions

Dimensions of Weld Stand: 1860 mm x 3550 x 1860 mm.

| Weld Stand | Dimensions [mm] |

| Width | 1860 |

| Height | 3550 |

| Depth | 1860 |

Documents

Weld Stand - MIG/MAG welding solution for 2G/3G position (CS/SS)

Weld Stand - Arc TIG welding solution - 2G position (SS)