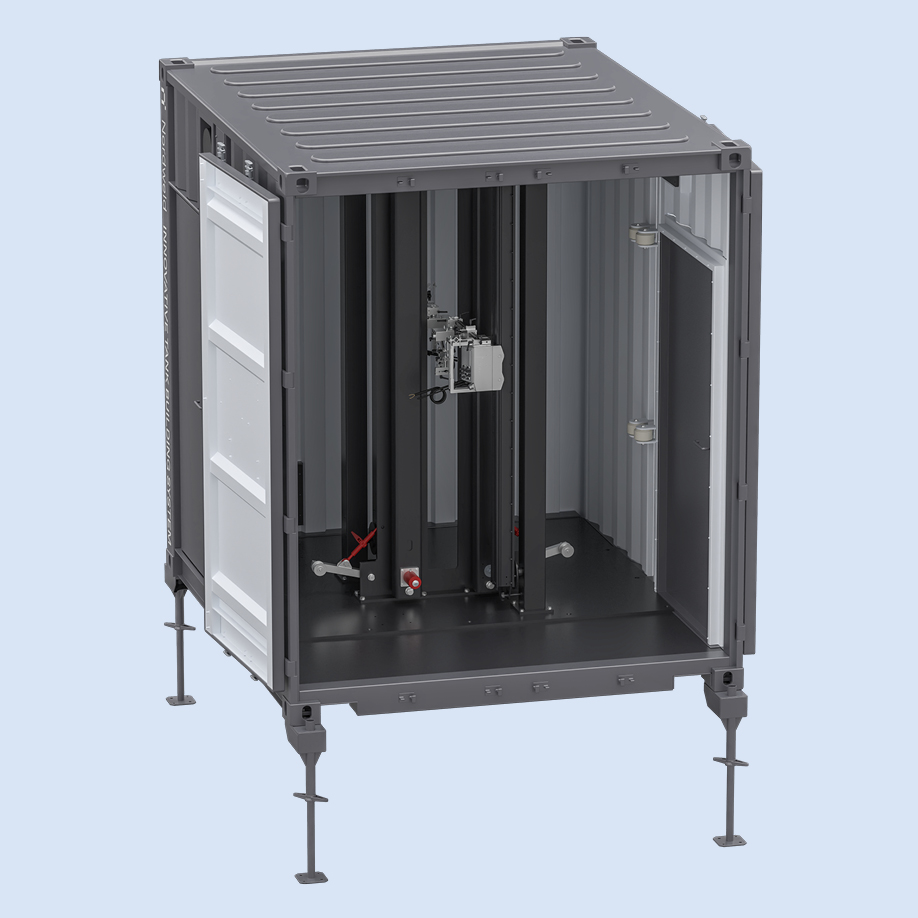

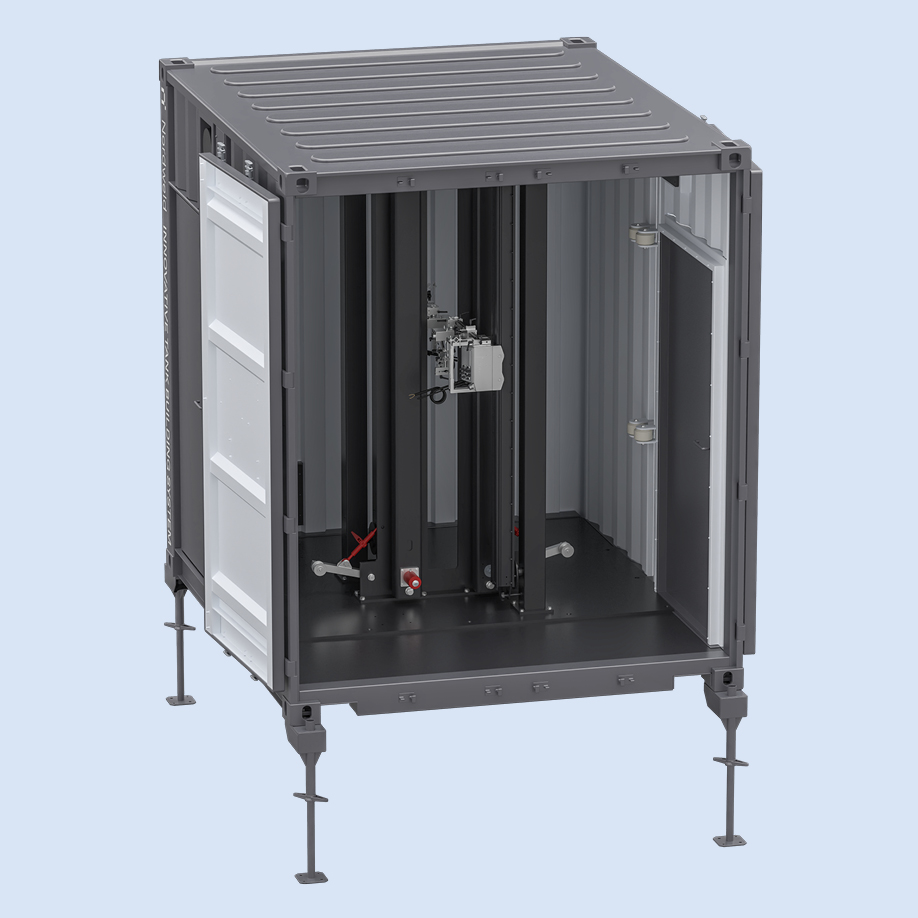

Welding Station for Plate Track

Automated container designed for the vertical assembly and welding of sheet metal plates. The system securely locks two sheets in a vertical position using hydraulic actuators, ensuring precise alignment before welding.

This technology guarantees stable and uniform pressure along the weld joint, enabling high-quality, repeatable results.

Ask for an offer

Key advantages:

- Fast and reliable clamping – Hydraulic actuators provide strong, even pressure across the sheets, minimizing the risk of movement or misalignment during welding.

- High weld quality – The stable positioning of sheets reduces deformation and ensures consistent, accurate welds.

- Improved efficiency – Automated clamping significantly reduces preparation time, increasing throughput and overall productivity.

- Versatility for various sheet thicknesses – Quick and easy adjustment accommodates different sheet dimensions, enhancing the flexibility of the system for various production needs.

- Weather protection for consistent weld quality – Welding is performed inside a fully enclosed container, shielding the process from wind, rain, and temperature fluctuations. This controlled environment ensures consistently high weld quality and stable working conditions, regardless of the season or external weather conditions.

The unique characteristics

- 10ft HC Customized container with 2 entrance doors

- Electrical central 32A

- Internal lightning

- Hydraulic plate clamping device

- 2 × Gullco 300Kat (new model) carriage with an oscillation unit

- 2 × C/W Foam transportation case

- Plate height for max 2000mm plates

- 2 x Deep section track – inside/outside